IperionX Limited has agreed a contract with GKN Aerospace to supply titanium plate test components manufactured using IperionX’s advanced titanium technologies.

Titanium plays a critical role in many aerospace systems, and GKN Aerospace has demonstrated expertise in building complex titanium components for civil, aerospace and military markets, including authoritative aircraft and missile models.

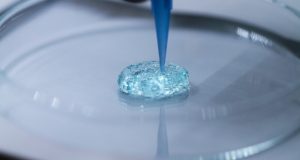

One sensational aspect of this merger is the implementation of IperionX’s 100% recycled titanium powder, made from GKN’s titanium waste. This emphasizes the collaboration’s environmentally conscious approach. IperionX’s breakthrough hydrogen sintering and phase transformation (HSPT) technologies – processes that optimize the microstructure of titanium to achieve strength and fatigue properties comparable to rolled titanium alloys – will play a role here.

“GKN Aerospace is a leader in sustainability and the precision manufacturing of titanium components for the aerospace, space and military markets,” said Taso Arima, CEO of IperionX. “We are very proud to be working with GKN Aerospace to commercialize our market leading high-performance and sustainable titanium products.”

Titanium is known for its high strength-to-weight ratio as well as its heat and corrosion resistance. However, the traditional production of titanium using the “Kroll process” used since the 1940s is both energy and cost intensive and results in significant greenhouse gas emissions. IperionX’s patented titanium production and manufacturing technologies promise to produce high-performance titanium products with lower energy use and cost, and zero Scope 1 and 2 emissions.

In the U.S., where over 95% of the titanium metal needed for advanced industries is imported, IperionX intends to bring titanium mineral and metal production back into the country, reduce heavy reliance on primary titanium imports from abroad, and strengthen the supply chain with lower cost and more sustainable titanium products.

With a focus on sustainability, cost-effectiveness and performance, this collaboration appears to be a constructive step toward a greener and more resilient aerospace industry that manages the balancing act between technological innovation and environmental responsibility. Technology watchers will eagerly follow the developments resulting from this partnership.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.