In a new YouTube video, Dr. D-Flo shows step-by-step how unused 3D prints, misprints and household plastics can be recycled into 3D printer filament.

With the help of shredders, extruders and pelletizers, production waste can be recycled. However, the process is quite costly: For 1 kg of filament, Dr. D-Flo needs about 2.5 hours. For household plastics such as PET bottles, recycling is even more difficult.

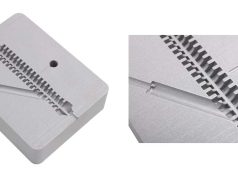

According to Dr. D-Flo, unwanted 3D prints made from PLA plastic are particularly well suited for recycling. With PET bottles, the material must first be shredded and extruded several times to produce a usable filament. In particular, the irregular shape of the plastic shards makes further processing difficult.

Despite the effort, recycling is worthwhile for environmental reasons. Dr. D-Flo makes it clear in his video that special industrial facilities would be needed to make recycling of household plastics truly efficient. Nevertheless, his experiment shows that 3D printing waste can be almost completely converted into new filament with a little time.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.