Lloyd’s Register, an organisation dedicated to research and education in science and engineering, has launched a new global certification framework as a “best practise” for manufacturers as well as end users of 3D printed equipment and components.

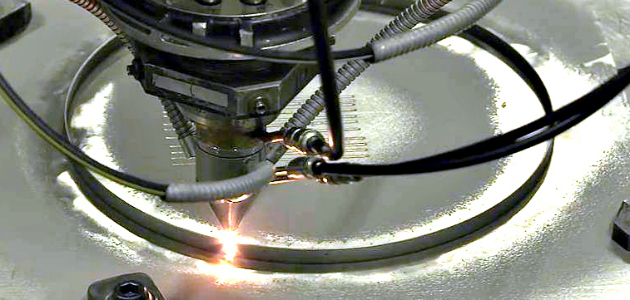

The guidance notes give operators and manufacturers in the energy and marine industries confidence in metallic equipment and components produced with additive manufacturing technologies. It represents a move by the leading integrity, compliance and specialist risk consulting services group, together with engineering research and technology firm TWI, to help industry harness the technology.

Chris Chung, Head of Strategic Research at Lloyd’s Register Energy, said: “As the Lloyd’s Register Energy Technology Radar survey suggests, AM will have a major impact in the oil and gas industry in the next five years. That is why last year, together with TWI and a number of industry partners, we brought together research and development efforts with real-world AM practices.” He added: “Our new certification guidelines, launched today to industry, are already being used by companies in this joint industry project to gain early certification of AM components.”

You can get your complimentary copy of the “Guidance Notes for Additive Manufacturing of Metallic Parts” here.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.