A new study by researchers at Monash University and the Arts et Métiers Institute of Technology demonstrates an innovative process to produce biomimetic materials for tissue engineering.

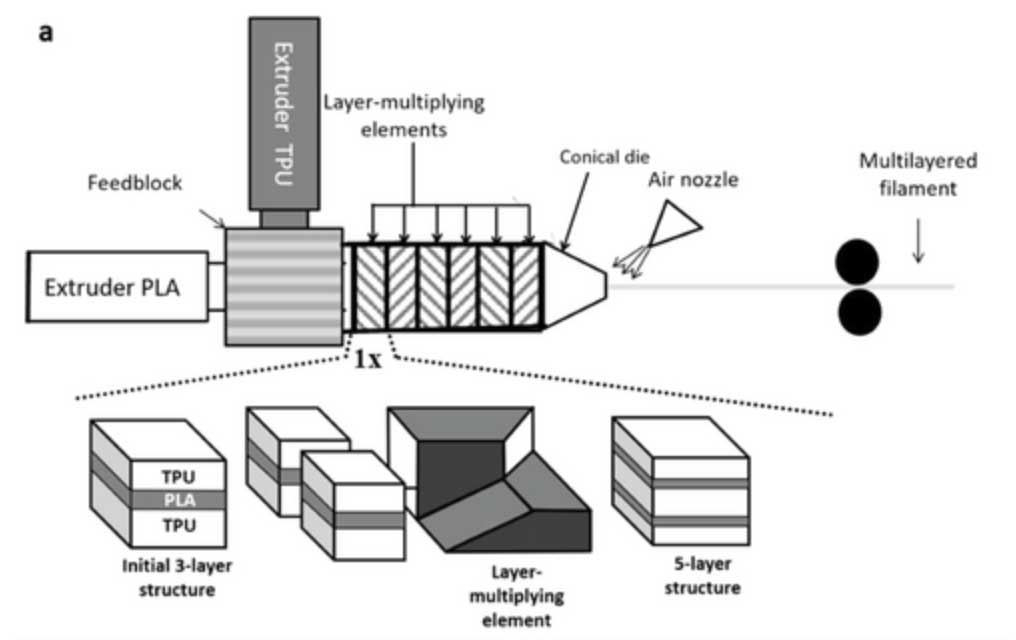

The scientists combined a co-extrusion process with 3D printing to create alternating layers of polymers PLA and TPU. This allowed the layered structure to be maintained in 3D printing, enabling improved adhesion between the polymer phases.

Depending on the co-extrusion setting, filaments with variable layer thickness could thus be created. In 3D printing, this resulted in constructs with nanolayers of the polymer phases. This led to an improvement in certain mechanical properties.

Tests with rat cardiac muscle cells showed that the layer structure had an influence on the cells’ alignment, morphology and functionality. The researchers see great potential for the technique in the production of scaffold materials, such as for bone or heart regeneration.

The innovative combination of co-extrusion and 3D printing opens up versatile possibilities for the development of biomimetic materials. The full paper, titled “Fabrication of Architectured Biomaterials by Multilayer Co-Extrusion and Additive Manufacturing,” can be read here.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.