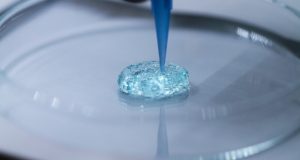

ASTM International’s Additive Manufacturing Technologies Committee (F42) has developed a new standard for maraging steel using the powder bed fusion process.

This type of steel, useful in industries such as automotive, sporting goods, and aerospace, strengthens through heat treatment and provides high strength and toughness while maintaining ductility, weldability, and dimensional stability.

David Rosen, senior scientist at the Agency for Science, Technology and Research and a member of ASTM, emphasizes the role of the new standard (to be ASTM F3607) in ensuring the quality of additively manufactured parts made from maraging steel.

“Maraging steel has high strength and toughness without losing ductility, weldability, and dimensional stability,” says Rosen, principal scientist at the Agency for Science, Technology and Research. “If maraging steel is used to replace lower grade steels, resulting parts may be lighter and stronger, which can have positive benefits on fuel efficiency of cars and airplanes, for example.”

Find out more about ASTM International at astm.org.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.