A research team from Nanyang Technological University (NTU) in Singapore and the University of Cambridge has unveiled a new 3D printing approach that can produce customized metal parts. This method allows different properties, such as different strengths, to be integrated into one metal part.

The breakthrough technique differs from conventional metal processing methods because it does not require additional raw materials or complex machine treatments. In practice, this could reduce manufacturing costs.

In addition to the ability to incorporate different degrees of strength in one metal part, the process also offers potential for other specific properties, such as different electrical conductivities or corrosion resistances within the same part.

Prof Gao, from NTU’s School of Mechanical and Aerospace Engineering (MAE), said: “Our method opens the way for designing high-performance metal parts with microstructures that can be finetuned to adjust the parts’ mechanical and functional properties, even at specific points, and allowing them to be shaped in complex ways with 3D printing.”

A prominent feature of the new approach is the ability of manufacturers to target the nature of the internal microstructure and the location of its formation in the metal.

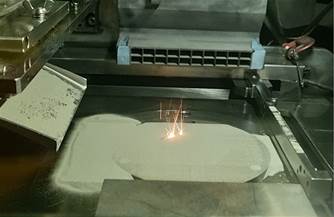

Dr. Gao Shubo, a scientist at NTU, played a key role in the research. He looked for ways to change the microstructures of 3D-printed metals without “hitting” the metal. He discovered that the metal’s microstructures can be reconfigured by rapid expansion and contraction during the 3D printing process.

The team conducted experiments with 3D-printed stainless steel that confirmed Dr. Gao’s theories. By fine-tuning the 3D printing process, the scientists were able to produce metals with different microstructures that had the exact stronger or weaker areas they wanted.

“Our strategy can target specific sites in the metal, which allows manufacturers to design and create complex microstructures that allow the properties of the metal to be customised to a degree not seen before. For instance, the same metal can have contrasting properties in the same part,” said Dr Gao Shubo.

The new method was presented in the journal Nature Communications in October 2023 and demonstrates NTU’s commitment to advancing interdisciplinary research of high importance.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.