The startup Orbital Composites wants to revolutionize the wind power industry by manufacturing rotor blades for wind turbines directly on site using 3D printers and robots. According to CEO Amolak Badesha, the complex logistics involved in transporting the rotor blades, which are often over 70 meters long, will be eliminated in the future.

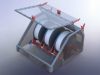

With the help of 3D printing from composite materials, the rotors are to be produced significantly faster and more cost-effectively than with conventional manual processes. The entire production technology can be packed into containers and transported flexibly to the wind turbine installation site.

Initial tests show that manufacturing costs can be reduced by up to 25 percent compared with offshore production. In addition, larger rotor blades are possible for greater energy yield. Plans also call for full 3D printing of towers and other wind turbine components.

A planned collaboration with the U.S. Department of Energy will also develop a cable robot for 3D printing to manufacture turbines more efficiently on site. Orbital Composites says the process can significantly scale wind power. The first 3D-printed demo rotors are expected to be unveiled later this year.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.