Örebro University invests in revolutionary SLS 3D printing technology by renting Gravity, the SLS 3D printer from Wematter. The signed contract is evidence that Swedish Wematter has an attractive offering for academia and research institutions. Based on the experiences from collaboration with KTH, Linköping University, Sahlgrenska, Akademiska, and Chalmers, Wematter now closes a contract with another prestigious Swedish educational institution – Örebro University.

The success in the educational sector is linked to Wematter’s intense focus on high-performance materials, in combination with user-friendliness and decentralized material development, which was a part of the latest Deep Space software release. The Gravity SLS 3D printer Wematter meets all the criteria set up by such educational institutions. The Wematter solution also facilitates complex collaboration between industry, institutions, professors, and students.

Wematter’s 3D printer will also benefit companies in central Sweden at large. A Gravity ecosystem on-site will enable Örebro University to develop a new optimization platform for SLS 3D printed fiber-reinforced components. The platform will be developed by Örebro University and will increase the additive manufacturing competence in the region.

“Örebro University is yet another university that invests in an SLS 3D printer from Wematter. We are happy to have found a collaboration that will strengthen both Wematter’s position in material science, and increase the capabilities of Örebro University”, says Robert Kniola CEO & Co-Founder at Wematter.

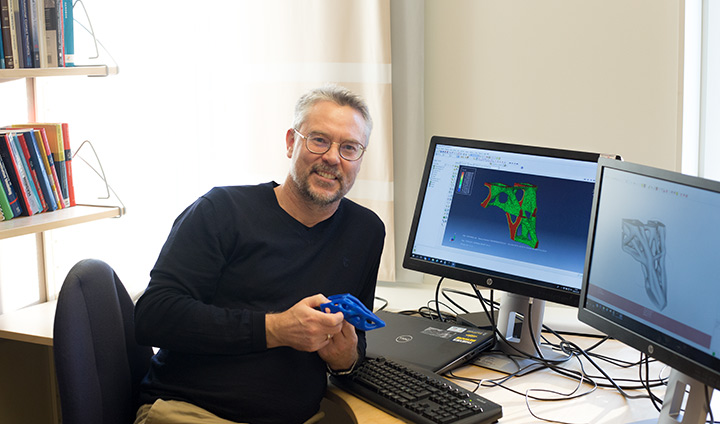

“The development of 3D printing is going at breakneck speed, with new, better machines and materials being launched continuously. 3D printing creates unique opportunities for the design of ultra-lightweight constructions similar to those found in nature, for example, the skeletal construction of birds. But to make full use of this potential, our designers need to see the possibilities and learn to design in new ways and not use traditional design methods such as turning, drilling, and milling”, says Niclas Strömberg, Professor of Mechanical Engineering at Örebro University.

Wematter offers high-performance polyamide materials reinforced with glass fibers as well as carbon fibers in the company’s Aurora family of SLS powders which are the most preferred materials for the aerospace and the automotive industries, as well as specialty industries. The collaboration with Örebro University will increase the understanding and capabilities for a future roadmap for fiber material developments.

Niclas Strömberg continues: “The group Mechanics & Materials (M&M) at Örebro University works on the development of such a new design methodology based on topology optimization and network structures. In a new 3-year project funded by Region Örebro, M&M will be given the opportunity to demonstrate its design methodology for ultra-lightweight components printed in Wematter’s SLS 3D printer”.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.