Researchers at the US Department of Energy’s Oak Ridge National Laboratory have discovered how to avoid costly and potentially irreparable damage to large metal parts produced by additive manufacturing caused by residual stresses in the material.

Residual stresses are a common cause of cracks and other damage in additively manufactured metal components, affecting the reliability and lifespan of these parts. “This is applicable to any metal 3D-printing process, since the general mechanics of deposition is similar across all AM processes,” Mathews added.

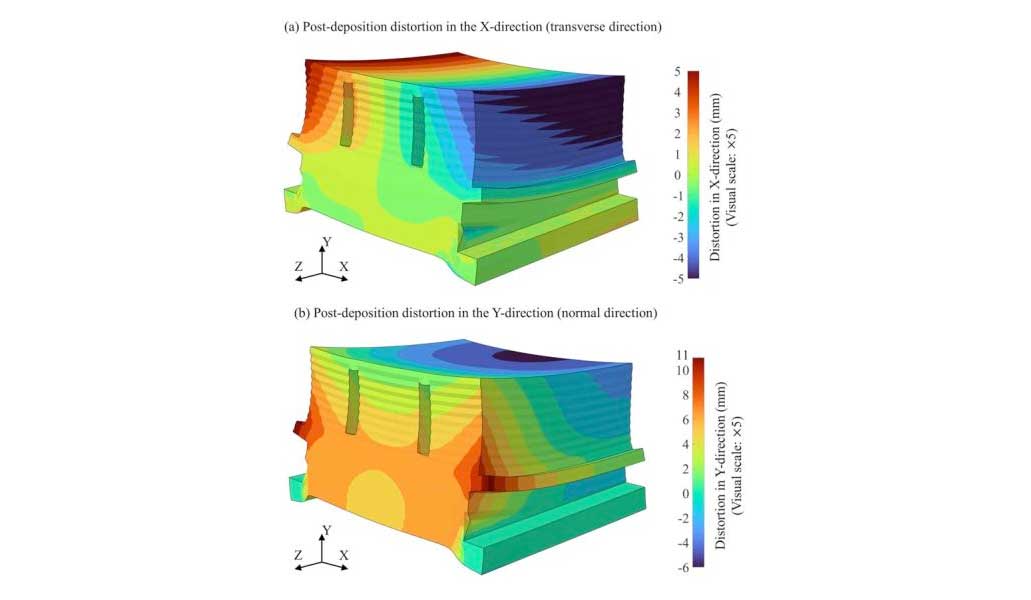

Through the use of computer-aided modeling, Ritin Mathews’ team identified how large, additively manufactured metal parts can develop significant residual stresses. These stresses lead to cracking during the printing process and increase as the material cools, ultimately weakening the metal structure and causing permanent damage.

The researchers were able to show that certain adjustments in the manufacturing process, such as the targeted addition of support material at critical points, can significantly reduce the accumulation of residual stresses. “Adding material in critical regions mitigates the accumulation of stress,” Mathews said.

“The presence of high-magnitudes of RS can cause cracks to develop in the build … reducing the integrity of components, leading to lower strength and fatigue characteristic,” Mathews and his coauthors write in a paper published in the 11th CIRP Global Web Conference (CIRPe 2023).

In addition to Mathews, the authors were Jaydeep Karandikar, Christopher Tyler and Scott Smith, all from ORNL’s Manufacturing Science Division.

This approach could improve the reliability of 3D printing in various industries and set a new standard for manufacturing large metal parts. The research, funded by the Department of Defense’s Industrial Base Analysis and Sustainment Program, was conducted at ORNL’s Manufacturing Demonstration Facility, a center dedicated to innovating and transforming the U.S. manufacturing industry.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.