The Innovate UK-funded OverHiPP project, short for “Over-printing with High Performance Polymers”, represents a significant advance in hybrid manufacturing technology. Within this two-year project, GRM, a TriMech Group company, and five other partners are working to develop and optimize a new technique for over-printing 3D-printed material onto composite panels.

This innovative approach combines advantages of existing techniques such as overmolding, resin transfer molding (RTM) and 3D printing to enable low tooling costs, increased flexibility, fast material changeover and low material waste.

One of the main problems in this area is the lack of knowledge and technology, particularly in relation to the simulation of 3D printed structures. GRM Consulting, specializing in design and topology optimization software, is working on solutions to improve the accuracy of digital twins to provide insight, guidance and confidence in 3D printed components.

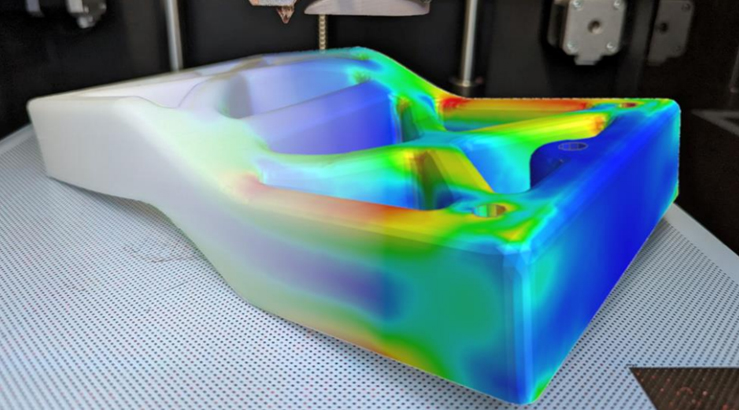

The challenge in modeling 5-axis 3D printed structures lies in their highly anisotropic nature, which makes it difficult to accurately represent these properties in a digital twin. GRM has overcome this hurdle by developing software that can automatically replicate a tool path in an FE model. Using a proprietary G-code reader that can analyze tool path properties and convert them into a digital twin format, this software enables the inclusion of precise filament orientations and fill cavities in structural simulations.

A test investigating the feasibility of 3D printing a hypercar footrest demonstrated the power of this new software. Topology optimization studies were conducted to determine key load paths and structural performance, from which a CAD model was created for manufacturing with a high-temperature polyamide from Lehvoss. The simulation results showed a five-fold difference in stiffness and strength depending on the direction of compression.

The OverHiPP project makes it possible to virtually model and analyze 3D-printed structures with an unprecedented level of detail. Accurate digital twins can now be generated that enable precise design decisions and show a strong correlation to physical tests. As a result, different printing strategies can be examined in detail, weak points and failure modes can be assessed prior to production, leading to more efficient workflows and more consistent, successful results.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.