Industrial production of titanium alloys has always been plagued with problems related to quality and waste disposal. A team from Hong Kong Polytechnic University (PolyU), in collaboration with RMIT University and the University of Sydney, has successfully used additive manufacturing to solve these long-standing problems in titanium alloy production.

Titanium alloys are essential lightweight materials in many applications. Titanium alloys produced with 3D printing could reduce costs, improve performance and make waste management more sustainable.

The research team has developed a new, robust and ductile titanium alloy (α-β-Ti-O-Fe alloy) using 3D printing. This was achieved by incorporating oxygen and iron, the two most potent stabilizing and strengthening elements for α-β-titanium alloys.

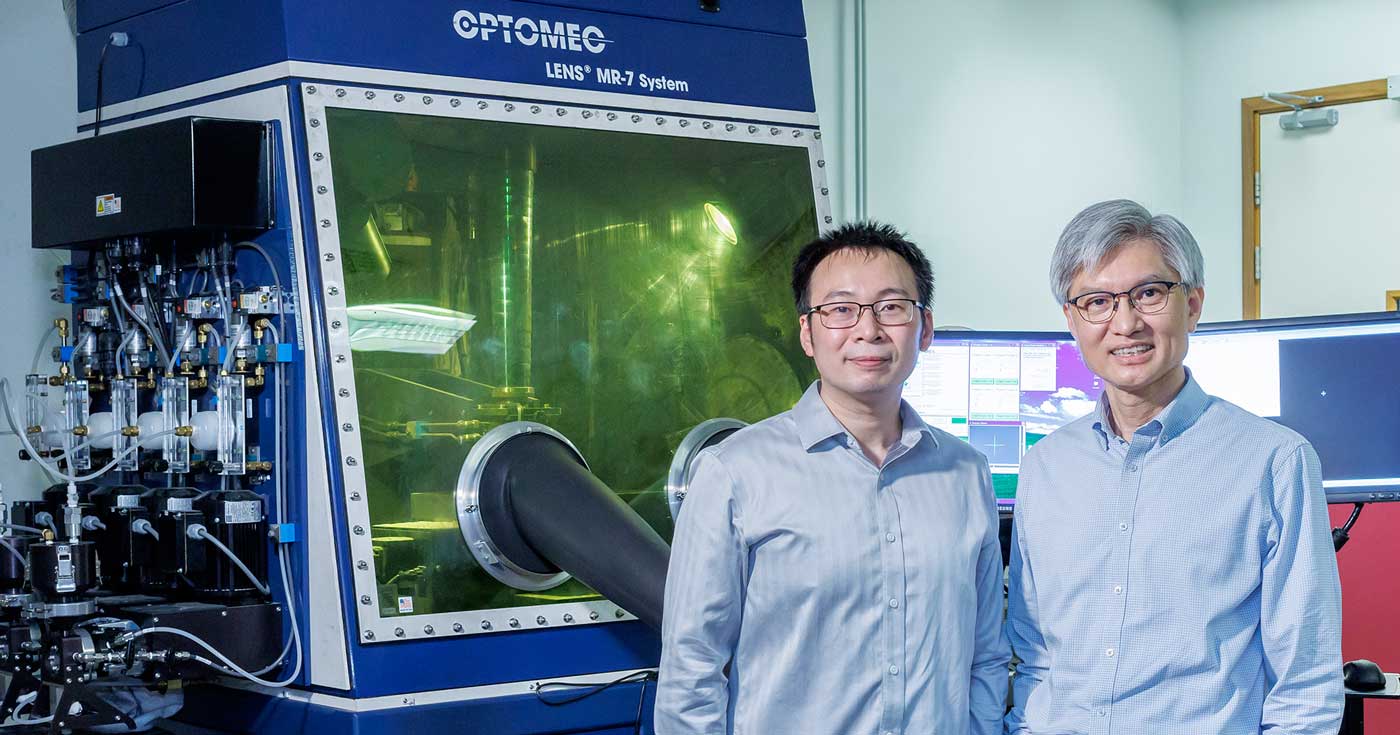

Dr Zibin CHEN, Assistant Professor of the Department of Industrial and Systems Engineering at PolyU, an awardee of the Young Innovative Researcher Award 2022 and a leading author of the research, stated, “Our work can facilitate the recycling of more than 10% of the waste generated by the metal alloy production industry. This can significantly lower both material and energy costs for industries, contributing to environmental sustainability and carbon footprint reduction.”

Additive manufacturing enables the production of complex metal parts in a single step and the creation of structures and compositions that are inaccessible to conventional methods. It also allows microstructure customization, resulting in higher strength, flexibility, and corrosion and water resistance.

Prof. Keith K.C. CHAN, Chair Professor of Manufacturing Engineering at the Department of Industrial and Systems Engineering at PolyU and a co-author of the study, noted, “This work can serve as a model or benchmark for other metal alloys that use 3D printing to enhance their properties and expand their applicability. Metal 3D printing is an emerging field, and it will take time before it is widely adopted in materials manufacturing.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.