A research team from Skoltech has improved the properties of a polymer used for 3D printing. By adding boron nitride “flakes” to the photopolymer, the scientists managed to double the material’s thermal conductivity. This could prevent microchips encapsulated with the polymer from overheating, allowing for smaller and more powerful microelectronic devices. The work was published in the journal Polymers.

“The printing technology we devised is a step toward fusing microelectronics and additive technology,” study co-author Assistant Professor Stanislav Evlashin of Skoltech Materials commented. “While prior research tended to focus on printing conductive contacts for flexible electronics, we undertook to improve the properties of polymers suitable for microchip packaging — that is, for making the outer capsule of a microchip.”

As electronics get smaller, the problem of overheating becomes more acute. When squeezed into a smaller volume, the same amount of energy leads to faster overheating and device failure. To solve this problem, materials with better thermal conductivity must be used.

The chips themselves are made of silicon, which conducts heat well, but the capsule that houses the device could hinder heat transfer due to its low thermal conductivity. The material used for this outer packaging in devices with complex shapes is photopolymer – a paste that solidifies when exposed to radiation in a 3D printer. This photopolymer is the material whose properties were improved in the Skoltech study.

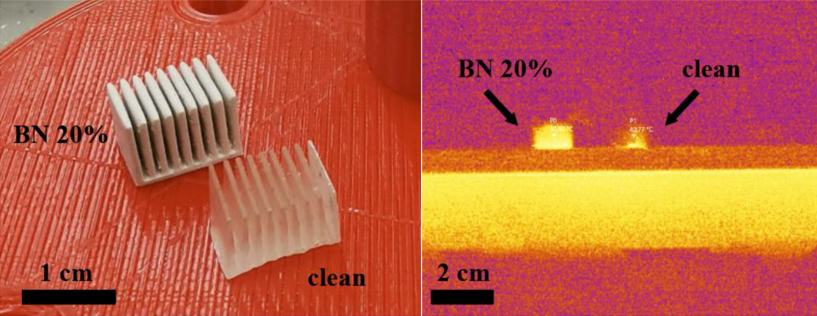

“The desirable characteristics for this photopolymer to be applicable in microchip packaging is that it should conduct heat well while not conducting electricity,” Skoltech Materials researcher and study co-author Daniil Chernodubov explained. “We went as far as to actually double the material’s thermal conductivity, without compromising its insulating properties or mechanical strength. To achieve this, we filled the polymer with another compound, called boron nitride, in the form of flakes, in the amount of 20% by volume.”

“The actual technique we used for printing is known as digital light polymerization,” Evlashin added. “It has a high resolution and is suitable for packaging devices of complex shapes. It can also be used to print the capsule directly on a silicon chip. The polymer’s enhanced thermal conductivity will ensure the stability and integrity of electronic components and allow them to work at higher operating characteristics.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.