One year ago, Michael Sorkin took on the task at Formlabs to grow the European market. We met him last week to recap the past year with him.

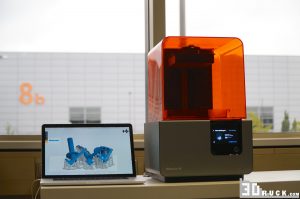

The change of the iGo3D founder to the manufacturer in Boston had already been announced in August 2015. In October, things really took off for the young manager. During the preceding March, Formlabs had launched the iGo3D as European distributor to gain a foothold on the local market. Additionally, almost exactly one year ago, the Form 2 was introduced on the Euromold in a live feed from Boston – a true sign for the commitment for the European market.

We have asked Michael to look back on what has been an eventful year. The General Manager for Europe looks back on how he took on his new role and grew Formlabs Europe from a small back room in Berlin with flickering lights and three motivated employees to something much bigger.

“A malfunctioning light bulb and three employees – but

incredibly talented people. These three employees were the basis on which I could count and build on the DNA of the company.

We have a very laid-back business climate. All of our meeting rooms are transparent. To us, this is the most important factor – internal transparency. Every employee can instantly message Max [Max Lobovski, founder of Formlabs] or me and say “this or that is s**t. We should do something about it.” It doesn’t matter which department the employee is working for. He will even be encouraged to do it. “

After having relocated to our current office, our team of 30 employees is already reaching its limits again. Besides the employee workplaces, there is also a showroom for customer workshops, events and internal parties. A while ago, there was a Halloween party.

„We are a team of 30 now and finally got a new office, directly behind the wall of our original one and with the exact same floor space. This makes it 600m² which is enough room for 70 to 80 employees. In Berlin, we have everything on-site – except for the engineering!”

The communication with our headquarters in Boston is perfect. There is a steady exchange of employees in both directions. This way, Formlabs can directly respond to the needs of its customers and implement their feedback.

„If you go from zero to one hundred in just 10 months, you get a lot of positive feedback. Our goal was to get the same customer satisfaction rate of 97%, we already had for Formlabs in the U.S. Now we are trying to top it!”

Originally, Michael had started at home with his first 3D printer, a Felix 1.0 Kit, followed by an Ultimaker Original. Now, he only has a 3D printer by Formlabs on the desk in his office which he uses for private projects as well. Only one week ago, he exchanged his Form1+ for a Form 2.

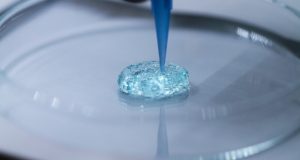

„I am printing on a weekly basis. I like to go scuba-diving and there are so many new solutions in this area that have not reached the „market“, yet. Especially the Tough Resin is perfect for this, water-resistant and robust. I used it to print a mount for the handle of my diving lamp. You can even bump against stones with it underwater. It really is super steady. And it perfectly fits my hand-print.”

The target group of Formlabs has always been professional users and the business to business (B2B) market. That is why the manufacturer is not only regarding its Form2 3D printer as a 3D printer but also as a user platform. The platform is supposed to meet the various needs of the customers. With its broad range of materials – not long ago, the manufacturer has broadened the range with a temperature-resistant and a highly resistant material – Formlabs offers a solution for everyone.

The special Dental SG material for dental technicians has paved the way to new markets as well. In order to meet the needs of professional users, Formlabs has launched its Pro Services. This way, you get personalised training sessions for the 3D printer for less than 500€ a year, advanced support via telephone and mail, as well as the Hot Swap exchange where the 3D printer is exchanged immediately when there is a defect to prevent downtimes.

The special Dental SG material for dental technicians has paved the way to new markets as well. In order to meet the needs of professional users, Formlabs has launched its Pro Services. This way, you get personalised training sessions for the 3D printer for less than 500€ a year, advanced support via telephone and mail, as well as the Hot Swap exchange where the 3D printer is exchanged immediately when there is a defect to prevent downtimes.

Especially in the dental sector, Formlabs is experiencing unexpected resistance:

„Especially in the dental sector, customers keep saying: „The printer is so cheap – why is that? Is it bad that it’s this cheap?“ They previously outsourced these services and now they can get a machine for a fraction of their monthly outsourcing costs. It delivers the same superb results on-site with a much easier workflow.

We are not cheap – Our price-performance-ratio is just right.”

The objective for Formlabs in 2017 is to gain new partnerships with customers to collaboratively master new projects. Whether it is large companies such as BMW, with which they have already established a dialogue or smaller customers is not important to Formlabs – “The project has to be relevant.” And, of course, they should help the team to grow even more. Michael is talking about “new exciting heads” that have yet to be employed.

„2017 is going to be a big year for us & we still have a lot in front of us!“

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.