Feldkirchen, October 2018 – German RepRap has been working for several years on the development of the 3D printing process Liquid Additive Manufacturing (LAM) and has already shown the first prototypes at the Formnext exhibition last year. LAM allows 3D printing of liquid or high viscosity material such as Liquid Silicone Rubber (LSR). Meanwhile, the process is ready for use in the industry and German RepRap presents the L280, the first production-ready LAM 3D printer.

LAM is a very interesting 3D printing process, because it works with a material that is in a liquid form that is vulcanized under heat exposure to its final form, contrary to the FFF technology – that is based on melting a material and solidifying again. This means that the individual layers deposited by the printer bond together, rather than simply welding together. In this way, objects can be produced that have the same properties as injection-molded parts – a clear advantage because insights from the 3D-printed prototype can be transferred directly to injection-molded serial parts.

With the LAM technology, even the application direction and thus the vulcanization at the macro molecular level can be influenced. In that case, the material partly offers better strength compared to injection molding. In addition, of course, all the benefits of additive technology such as freedom in design and filling the part of the interior with honeycomb or other structures can be used. DOW’s Liquid Silicone Rubber (LSR) is already being used in many companies for a wide range of products, this gives confidence to customers that want to use 3D printable LSR in the future.

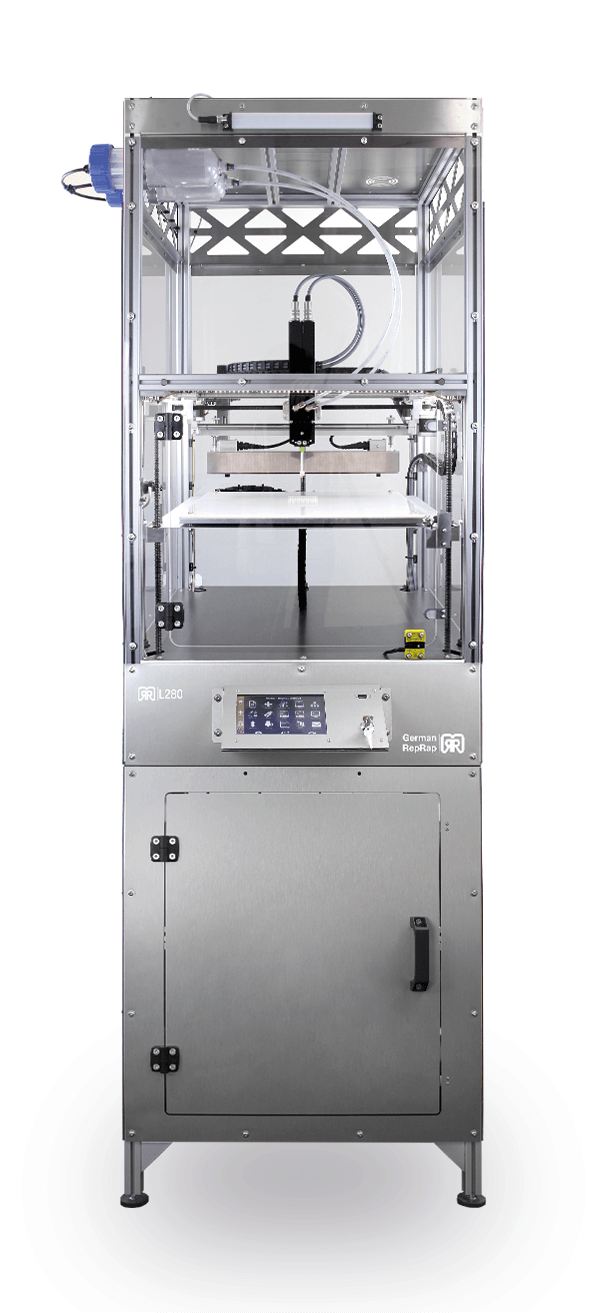

With the L280, German RepRap will present a series-ready LAM 3D printer at Formnext for the first time. The L280 offers a space of 280 x 280 x 200 millimeters (X x Y x Z) and a layer thickness between 0.22 and 0.9 millimeters. Nozzles with 0.23, 0.4 and 0.8 millimeter enable very accurate but relatively long lasting objects as well as less detailed but rapidly printed components. A heated print bed increases the adhesion of the printed parts and ensures optimal cross-linking. A high-temperature halogen lamp is used selectively in the process to accelerate the cross-linking. This significantly reduces printing time while improving print quality. Compared to conventional production processes such as injection molding, this often saves time.

The EVOLV3D ™ LC 3335 Liquid Silicone Rubber (LSR) material developed by DOW can be supplied in the form of cartridges, additional there is also an option for pails. Touch display and printing from the USB stick enable stand-alone printing and the L280 can also be connected to a network.

German RepRap has also thought about safety and installed a safety technology in the L280 that monitors the curing process and immediately stops the process in case of irregularities. A special light system provides information about the current status.

The L280 3D printer has proven its reliability in continuous operation in extensive tests and pilot applications in practice. For commercial use, where high availability and dependability are concerned, a maintenance contract and a professional on-site service is available as an option from trained technicians. In addition to the maintenance and repair of the 3D printer, this also includes software and hardware training. Individual requests are welcome at any time. The worldwide, certified German RepRap partner network ensures a reliable and professional service through a personal contact in almost every region.

More information about the product can be found on our website: https://www.germanreprap.com/printer/L280EN.aspx

Press contact German RepRap:

Lena Wietfeld

Tel.: +49 89 248 8986-0

Email: presse@germanreprap.com

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.