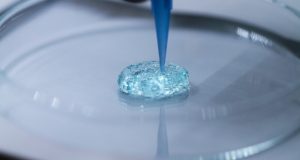

The Virtual Foundry, Inc. announced FFF Metal Microwave Sintering, a new technique in development for debinding and sintering FFF 3D printed metal parts. FFF Metal Microwave Sintering is an alternative to debinding and sintering in a kiln or furnace and offers a new way for people printing with Filamet metal filaments to get full metal parts.

“Since the beginning, our quest has been to Democratize metal 3D Printing,” says Bradley Woods, Founder and CEO at The Virtual Foundry. “The advent of a microwave sintering process for metal 3D prints is a tremendous shift in the momentum of this movement.”

Features and benefits of FFF Metal Microwave Sintering include:

- Equipment that’s easily accessible

- A much shorter processing time

- The possibility of higher temperatures than are available in standard table-top kilns

FFF Metal Microwave Sintering is still in the developmental stage. For more information on FFF Metal Microwave Sintering, visit https://thevirtualfoundry.com/2022/10/18/microwave-sintering/

For more information about The Virtual Foundry, please visit thevirtualfoundry.com.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.