3D printing has been around for much longer than most people realize, but the technology is just now progressing to the point where it will start to be seen in everyday life. The basic components of a 3D printer are a mechanical extruder, which could be thought of as the printing head, and the CAD software that operates the device. Both of these technologies have progressed exponentially in the past 30 years, and they will only continue to become more streamlined, efficient, and utility-oriented. Up until quite recently, 3D printers were limited to small, almost toy-like machines that did little more than produce different colored plastic baubles and other novelty items. Now, entirely new assemblies exist that produce large-scale, real-world items that have a tangible purpose. Below is a list with a few of the largest, most versatile 3D printers available today.

10.Norsk Titanium’s Direct Metal Deposition

Norsk Titanium is a Norwegian company looking to expand their production line to the United States. They’re currently planning to open a 200,000 square foot facility in a yet to be named state. Norsk’s newest titanium 3D printer is designed for producing raw titanium parts that go on to be finely milled into their specific components. The printer doesn’t take much space, measuring in at 120 x 120 x 180 cm.

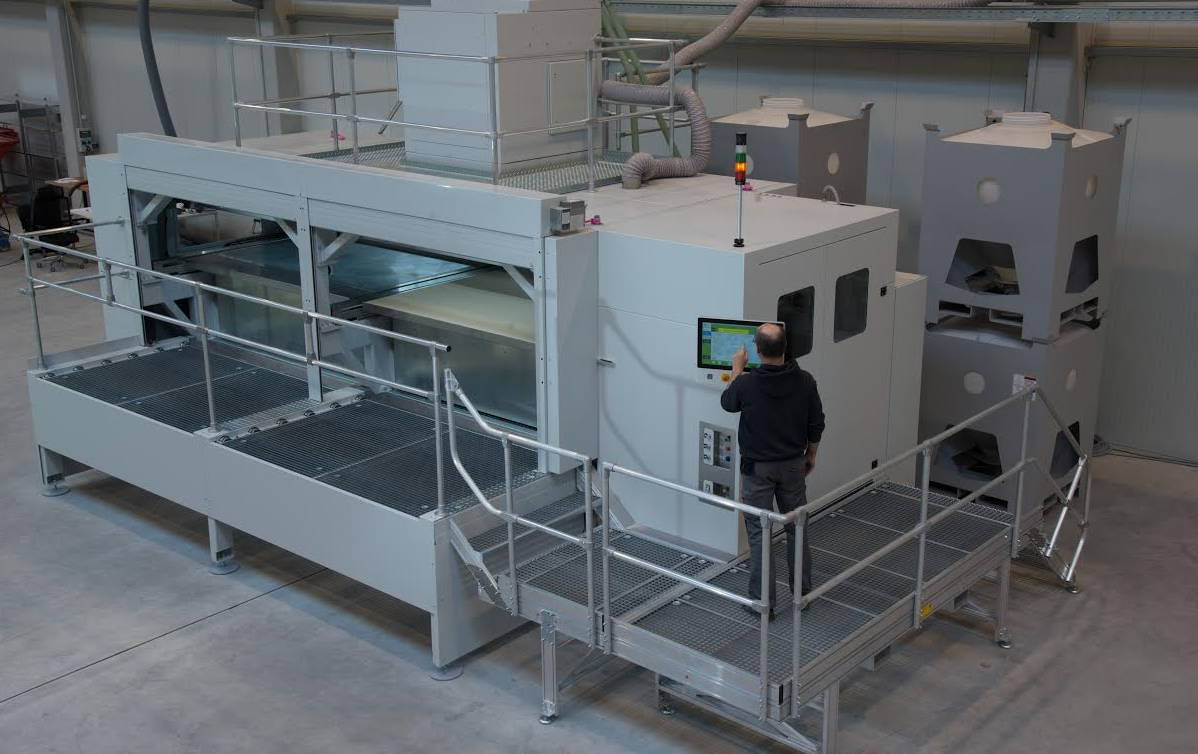

9.ExOne Exerial

The Exerial by ExOne is ideal for mass production, and ExOne has several facilities spread throughout the United States, Germany, Italy, and Asia. This industrial 3D printer uses sand to create complex cores and molds. A singular printer measures 838 x 403 x 495 cm, but it is possible for several Exerial machines to be attached in series, creating an assembly network for even more complex productions. This printer is also designed with two separate job boxes for the most utility possible.

8.voxeljet VX4000

The VX4000 by voxeljet is perfect for creating prototypes, complex components, and molds. The machine utilizes one of the largest build areas on the market for this style of 3D printer, measuring nearly 400 x 200 x 100 cm. It is capable of continuous printing, and the fast build speeds trump many of the competitors. The VX4000 is available from any voxeljet facility in Germany, India, the UK, and the US.

7.D-shape

Monolite UK is the parent company responsible for the D-Shape. This amazing printer is capable of producing an entire physical building, and could be used for the manufacturing of simple homes. It uses a sand/binder mixture to add layer after layer, and its 4×4 meter frame easily fits in many places. The D-Shape was original designed and built in Europe, but soon the technology will spread.

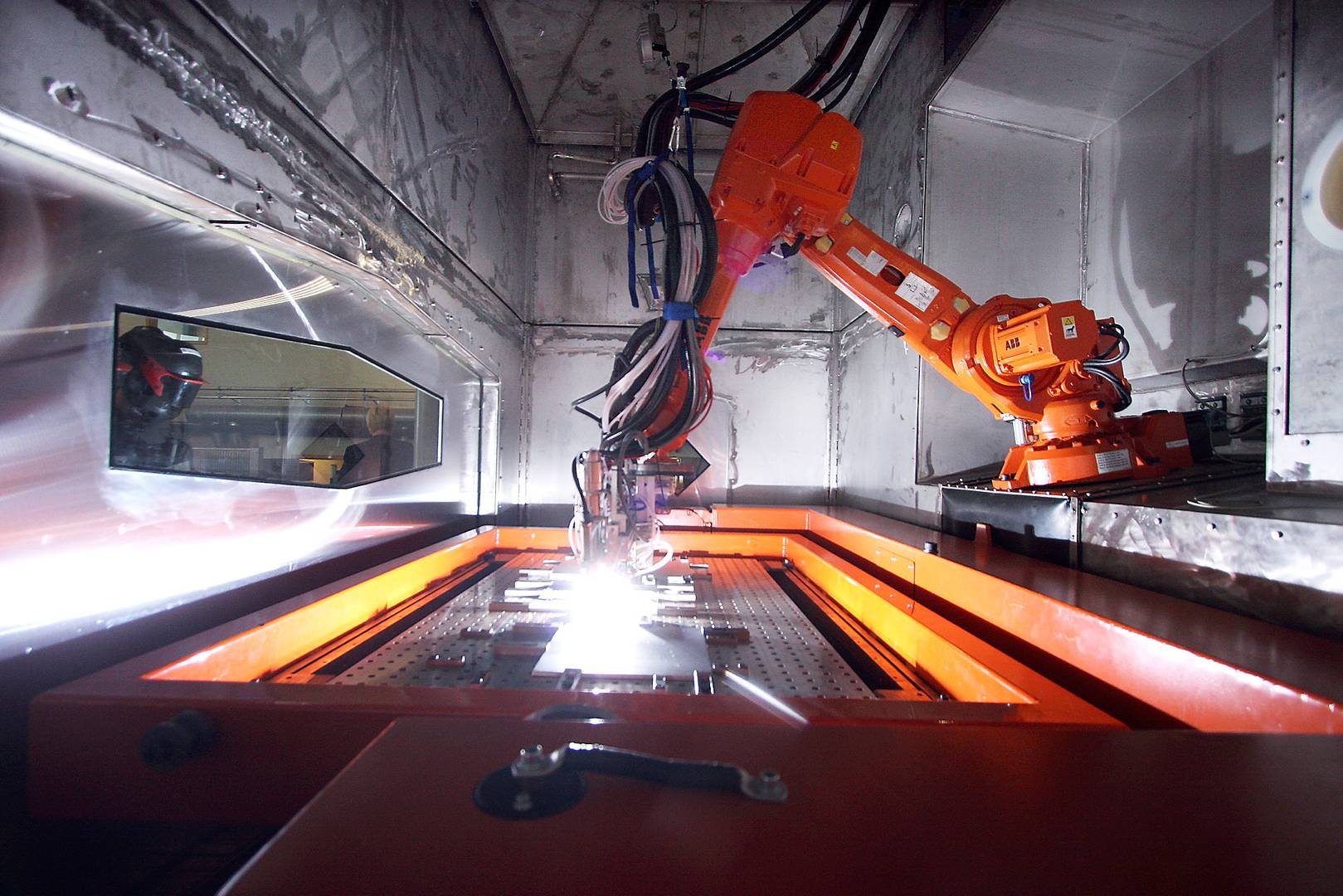

Sciacky, Inc. is headquartered in Chicago, Illinois, and their EBAM printer is revolutionizing the 3D printing industry. EBAM stands for Electron Beam Additive Manufacturing, which deposits individual layers of nearly any metal using an electron beam gun. This machine has one of the largest work chambers in the field, measuring 762 x 274 x 335 cm. The EBAM is the fastest metal 3D printer in the world, and it can reduce costs and build time up to 80%.

5.KamerMaker

The KamerMaker is not publicly available, since it was designed as a prototype. The machines rests in Amsterdam when it isn’t being demonstrated, and it is designed for the production of entire buildings. The print area for the KamerMaker is enclosed in a metal housing, and the internal build area is 2.2 x 2.2 x 3.5 meters. The printer uses recycled materials to produce components that then go on to be assembled into structures.

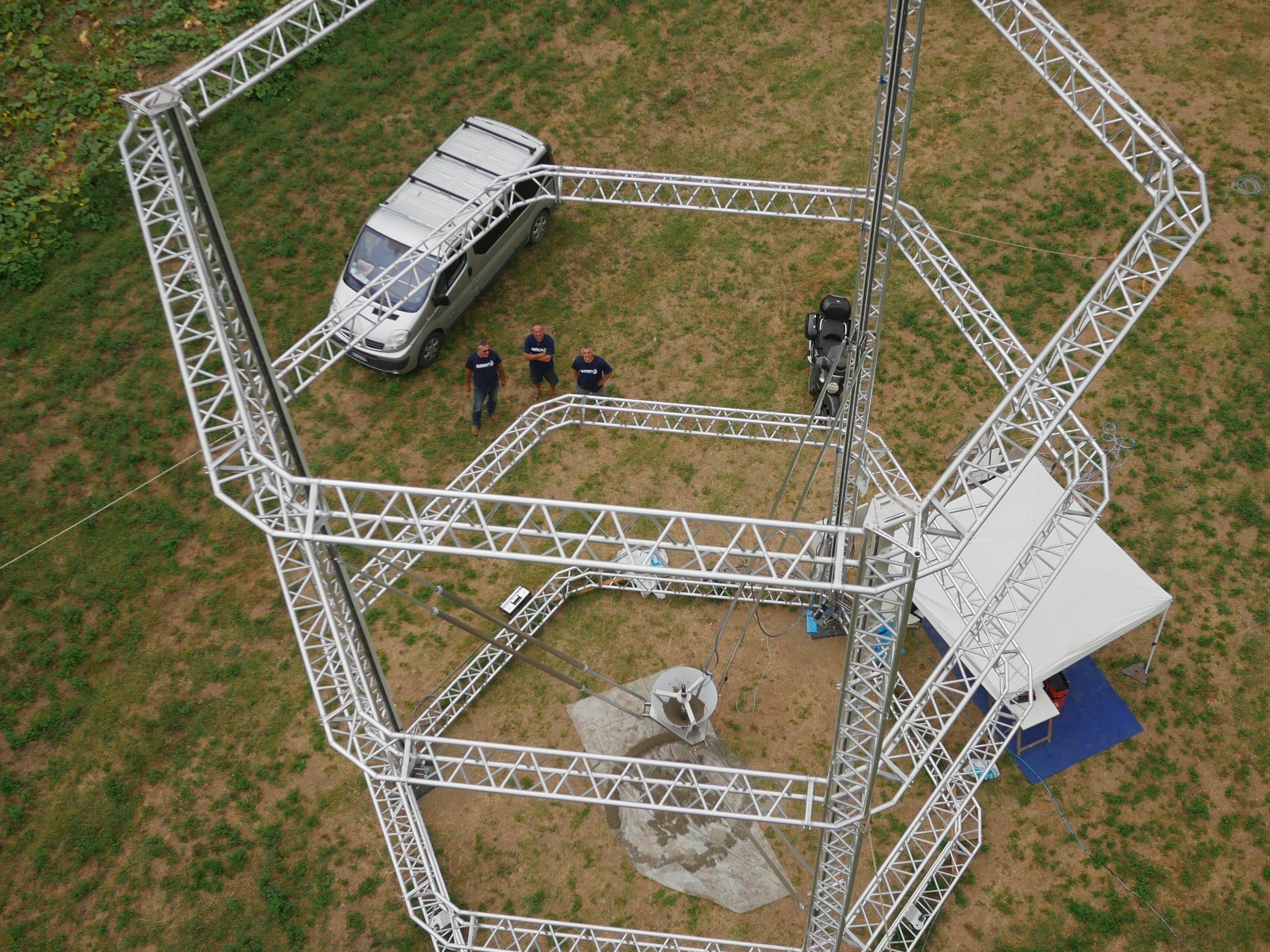

4.WASP GigaDelta

The WASP GigaDelta was designed in Italy to replicate the action of potter wasps that build their homes layer by layer from clay. The machine is nearly 12 meters tall and incorporates a build area beneath a lattice frame. This printer was originally created as a way of building cheaper homes with local materials. The machine uses clay to slowly build a home structure from the ground up.

3.Cincinnati Incorporated’s BAAMCI

The BAAM, or Big Area Additive Manufacturing, by Cincinnati Incorporated has shattered the previous notions about 3D printing. BAAM has a build volume of 2.1 x 4 x 1m and a deposition rate of 40 lbs./hr. This impressive system is capable of producing the body of a car within 2 days. The system is compatible with metal and polymer materials, and its applications are nearly endless.

2.BetAbram P1

The P1 by BetAbram is specifically designed for the production of large-scale homes, including those with multiple levels. The P1 has a 16 x 9 x 2.5 meters build area, and it uses concrete to print solid structures. BetAbram initially began producing their innovative machines in Europe.

1.Winsun

Winsun is based out of Shanghai, and they’ve been able to do something amazing with their 3D printing technology. Their proprietary printer (6 x 10 x 40 meters) is able to produce entire large scale buildings, including massive homes and apartment buildings. The machine uses recycled concrete and added steel framework. Winsun is capable of making cheap homes that appear to have been created through conventional means.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.