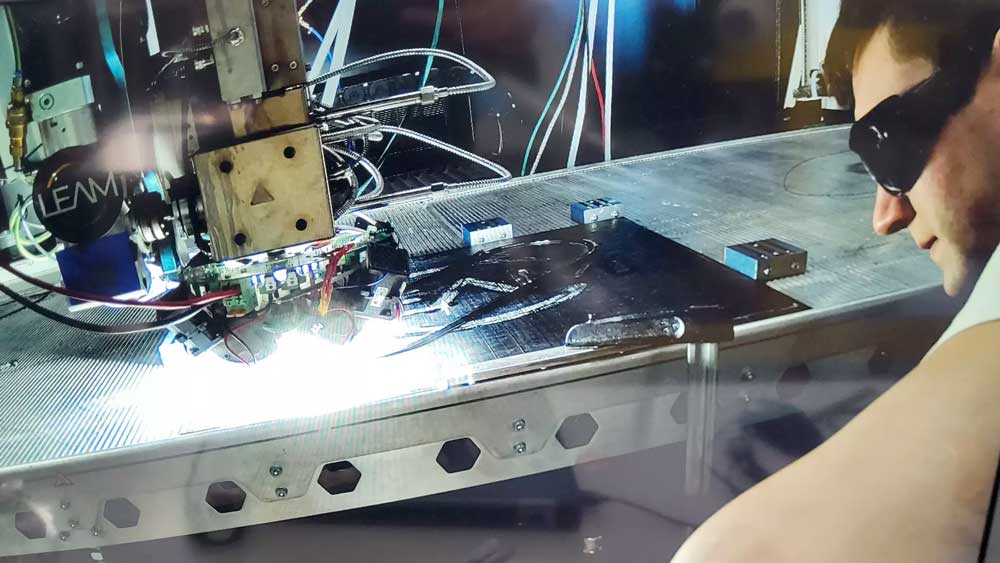

Tech start-up LEAM has succeeded in improving plastic 3D printing through the use of light alone. This is made possible by high-performance LEDs and the targeted delivery of focused light to the component. The three founders got to know each other during their time at the Chair of Carbon Composites at the Technical University of Munich (TUM) and have now used their knowledge to solve an industrial problem. Thanks to the new technology, companies will be able to print complex structures at a particularly high component quality at low cost in the future.

The LEAM technology, short for Light Enabled Additive Manufacturing, is designed to optimize the bonding between the material layers in 3D printing. LEAM’s solution addresses problems with the strength and quality of components by using focused light to heat the materials.

“The idea has been maturing for me since my Master’s thesis,” explains Patrick Consul, CEO and co-founder of LEAM. “Back then, I was working on sand cores made from high-performance materials for casting applications and wondered whether the complex structures that were possible with them could also be achieved in other ways.”

“It was immediately clear to us that we had a common basis for an innovative approach. But to really get there, we needed one more person,” explains Ting Wang, CTO of LEAM.

In contrast to conventional laser technologies, which are expensive and potentially dangerous for personnel, LEAM’s light technology offers a cheaper, safer and easy-to-integrate alternative.

The team sees great potential in the aerospace and prototyping industries, where complex components are required in small quantities. Supported by TUM and the TUM Venture Lab Additive Manufacturing, LEAM plans to bring its technology to market in 2025.

Patrick Consul concludes: “The system works, which we can now demonstrate in practice after years of development. There is no lack of interest from the industry, as we are solving a costly problem for our customers.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.