A team of chemists from MIT and Duke University has discovered an unusual way to make polymers stronger: they add some weaker bonds to the material.

These polymers are often used as components for cars or as “ink” for 3D printing. The scientists are now testing whether this approach can be applied to other materials such as tires.

“If you could make a rubber tire 10 times more resistant to tearing, that could have a dramatic impact on the lifetime of the tire and on the amount of microplastic waste that breaks off,” says Jeremiah Johnson, a professor of chemistry at MIT and one of the senior authors of the study, which appears today in Science.

“Polymer engineers know how to make materials tougher, but it invariably involves changing some other property of the material that you don’t want to change. Here, the toughness enhancement comes without any other significant change in physical properties — at least that we can measure — and it is brought about through the replacement of only a small fraction of the overall material,” says Stephen Craig, a professor of chemistry at Duke University who is also a senior author of the paper.

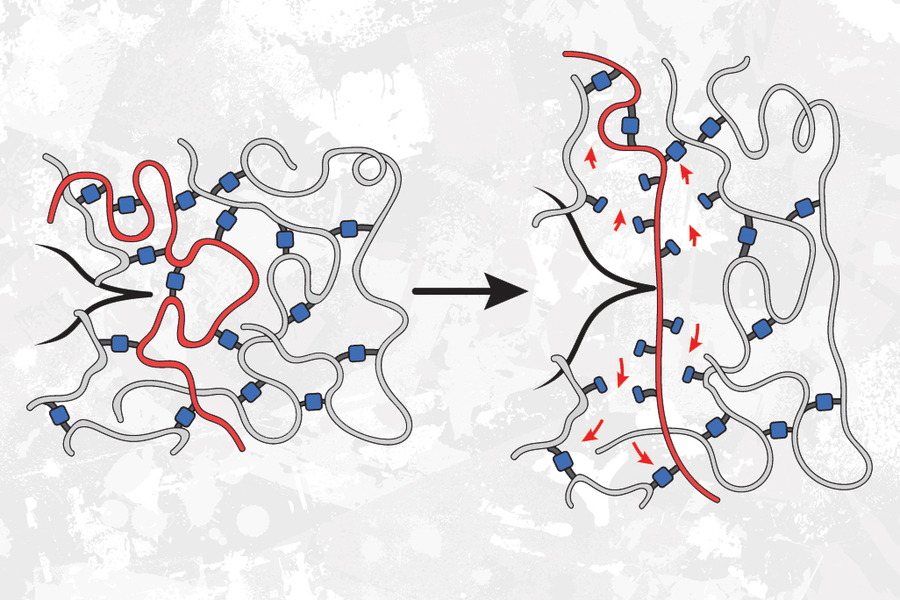

The researchers believe that the weaker bonds cause cracks to propagate through the material, avoiding stronger bonds, resulting in increased tensile strength.

“Even though those bonds are weaker, more of them end up needing to be broken, because the crack takes a path through the weakest bonds, which ends up being a longer path,” Johnson says.

The group’s work is part of the National Science Foundation-funded Center for the Chemistry of Molecularly Optimized Networks, led by Craig.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.