In a new study, a research team from North Carolina State University has shown that it is possible to create filters to capture carbon dioxide using 3D printing.

They printed a hydrogel material that can accommodate carbonic anhydrase, an enzyme that converts carbon dioxide and water into bicarbonate. The research suggests that 3D printing could be an efficient method for producing such filters.

“This manufacturing process, using 3D printing, makes everything faster and more precise,” said the study’s lead author Jialong Shen, assistant research professor of textile engineering, chemistry and science at NC State. “If you have access to a printer, and the raw materials, you can make this functional material.”

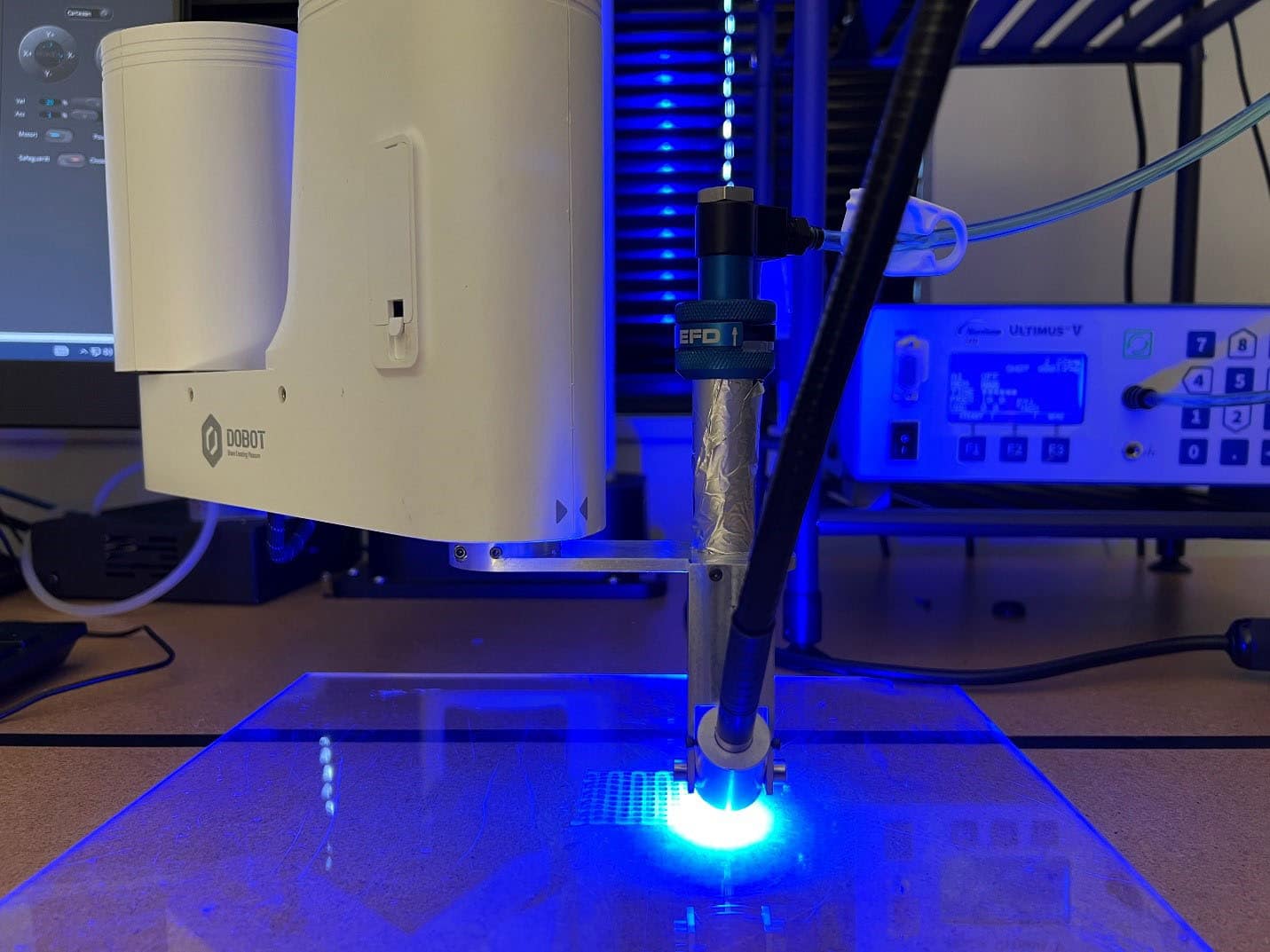

The researchers mixed a solution containing two different organic compounds and an enzyme and printed it out into thread-like filaments. They then solidified the material with UV light during printing.

“We formulated the hydrogel in a way that would be mechanically strong enough to be 3D printed, and also extruded into a continuous filament,” Shen said. “The inspiration behind our design was our own cells, which have enzymes packed into compartmentalized spaces, filled with a fluid. That kind of environment is good for helping enzymes do their job.”

In a small experiment, they found that the filter captured 24% of the carbon dioxide in a gas mixture. Although the capture rate is lower than previous designs, the researchers believe that increasing the diameter or stacking the filters could increase efficiency.

“In order to get a higher capture rate, we would need to make the filter larger in diameter, or stack more filters on top of each other,” Shen said. “We don’t think that’s an issue; this was an initial test at a small scale for ease of testing.”

“This work is still early stage, but our findings suggest there are new ways to make materials for carbon capture devices,” said the study’s co-corresponding author Sonja Salmon, associate professor of textile engineering, chemistry and science at NC State. “We’re offering hope for carbon capture.”

Find out more about the North Carolina State University at ncsu.edu.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.