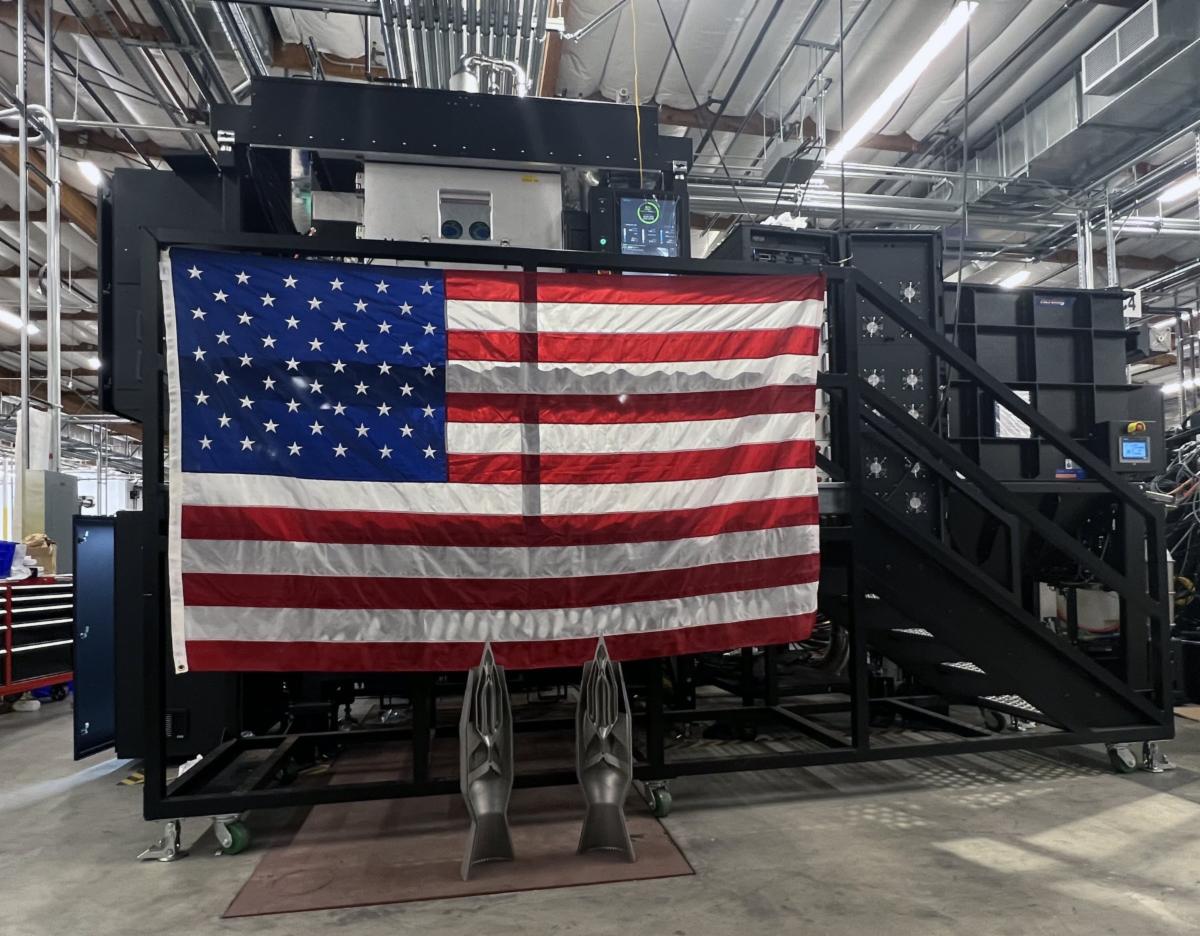

The additive manufacturing industry is taking a significant step forward with a partnership between Velo3D, Inc. and Bechtel Plant Machinery Inc (BPMI). The partnership aims to use Velo3D’s innovative 3D printing technology to more efficiently produce critical parts for the U.S. Naval Nuclear Propulsion Program. At the center is the Sapphire XC large format printer, calibrated for printing with 415 stainless steel and operated at ATI in Florida.

Velo3D’s additive manufacturing solution is characterized by a combination of advanced software and hardware, enabling the production of complex parts without extensive support structures. This technology breaks traditional manufacturing boundaries and enables novel designs that were previously unachievable. Of particular note is the printer’s ability to print overhangs beyond 45 degrees without additional supports, enabling a wider range of geometries.

“BPMI and ATI’s progressive approach to 3D printing is extremely forward-thinking and this new, revolutionary facility will significantly augment the U.S. Navy’s supply chain for maintenance, repair, and operations,” said Brad Kreger, CEO at Velo3D. “Both companies are early adopters of metal 3D printing and innovators in the manufacturing industry. We look forward to working with them as they support the U.S. Navy’s fleet, including its aging vessels.”

“Printers with larger build volumes and the ability to print with less support structures are ideal for U.S. Naval Nuclear Propulsion Program applications,” said Nathan Weiderspahn, BPMI Executive Manager, Industrial Base Management. “This additive manufacturing technology will greatly support our efforts in delivering new technology to the U.S. Navy and helping maintain its fleet of ships.”

“ATI will be able to more easily additively produce complex parts with fewer support structures, at lower angles, and larger sizes than ever before,” said Joe Thompson, General Manager of ATI Additive Manufacturing Products. “This enables us to broaden the scope of possible part designs for our defense and aerospace customers, enabling higher performance and better quality. The business opportunity represented by these previously unproduceable part designs is significant.”

The collaboration between Velo3D, BPMI and ATI symbolizes a turning point in the use of 3D printing technologies to support maritime defense readiness. Velo3D’s technology provides a scalable solution that paves the way for further innovation in additive manufacturing.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.