At this year’s Formnext, one of the leading additive manufacturing events, Wayland Additive is showcasing impressive advances in metal 3D printing. The focus will be on parts made from hard-to-machine metals such as titanium, carbon steel and tungsten.

Visitors to booth B139 in Hall 12 can marvel at Wayland’s Calibur3 metal AM system and view a variety of parts created with this machine. The Calibur3 system is designed to overcome common problems in metal 3D printing. It takes advantage of electron beam powder bed fusion (eBeam PBF) technology while addressing known limitations of the technique. A prominent feature of the system is Wayland’s proprietary NeuBeam process, which solves previous problems with charging in the EBM process.

Will Richardson, CEO at Wayland says, “As we champion the wider adoption of metal AM throughout industry, our focus on extending the material range available to companies is fundamental, and this is why at Formnext 2023, it is material processing and the open nature of our metal AM systems that is front and centre. NeuBeam® unlocks a swathe of complex metal production opportunities that current metal AM processes struggle with. This is because the process is compatible with a much wider range of metal powders, including but not limited to refractory metals and highly reflective alloys. The importance of this cannot be overstated as for industrial users of metal AM, the issue of materials is one that is consistently seen as a bugbear. Metal AM advocates are generally very keen on the advantages that metal AM processes can offer, but they invariably want these advantages with a known material quantity/quality that they trust. However, the nature of many AM processes mean they have to compromise on this and utilise new alloy derivatives created specifically for AM. This leaves them with two unknown quantities — a new process and a new material. This is where NeuBeam really breaks new ground, with the ability to process existing metal materials, which reduces the pain burden when qualifying new parts.”

The NeuBeam process allows the use of existing metal materials, reducing the qualification effort for new parts. Thanks to full charge neutralization during the build process, NeuBeam enables improved metallurgical properties. It also eliminates residual stress issues associated with other metal AM processes, producing denser parts with higher internal integrity.

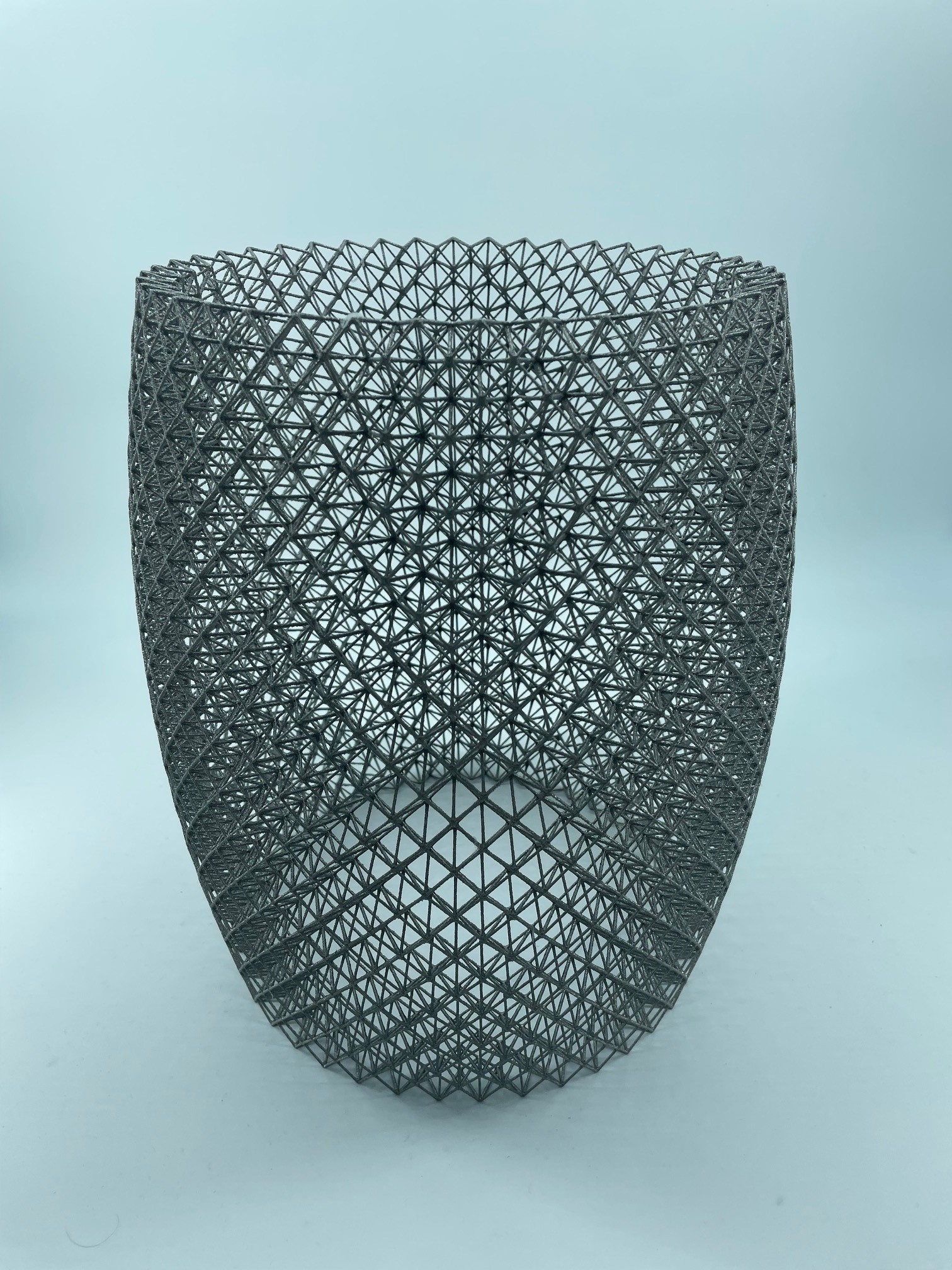

Richardson continues, “The elimination of residual stresses is a huge opportunity for the accelerated uptake of metal AM across a whole array of industry applications which we are eager to discuss with visitors at this year’s Formnext. It is fundamentally because of the fact that the process is what we call a ‘hot part’ rather than a ‘hot bed’ process. This means that the high processing temperatures required are applied to the part, not the bed, and this ensures free-flowing powder post-build (no sinter cake) and stress-free parts with reduced energy consumption. On our booth at Formnext visitors will see intricate large parts made from titanium (which when processed using NeuBeam® require no post process heat treatment); carbon steels (the NeuBeam® process enabling the printing of alloys with higher carbon contents that would otherwise crack when printed using existing laser PBF techniques); and fully dense parts in Tungsten (a refractory metal that requires exceptionally high temperatures to melt and which his prone to cracking in any other metal AM process).”

Wayland Additive’s presentation at Formnext 2023 shows that steady progress is being realized in the field of metal 3D printing. It will be interesting to see the development and adoption of these technologies in the coming years.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.