Hans Weber Maschinenfabrik, a renowned machine manufacturer from Kronach, Germany, announced that the company is a participant in Europe-wide research projects in the specialist network EmpowerAX with its WEBER additive division.

EmpowerAX is a long-standing project network that unites suppliers, users and machine manufacturers from all over the world to advance joint development topics in the field of additive manufacturing and to improve quality assurance. This pioneering project is coordinated by DLR (German Aerospace Center) and aims to intensify additive material extrusion with a focus on fiber reinforcement in industrial manufacturing.

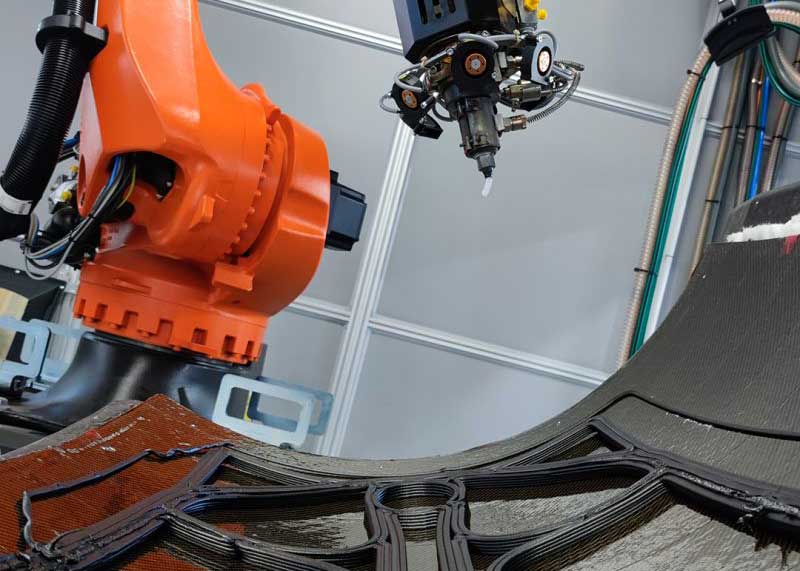

The current project explores imprinting on a multi-curved carbon fiber/epoxy shell with high-performance thermoplastics. The combination of thermoset and thermoplastic matrices as well as short- and continuous-fiber-reinforced materials enables the targeted optimization of mechanical component properties such as stiffness.

The demonstrator, which was produced by a conventional resin infusion process, consists of a carbon fiber fabric with a 0°/90° pattern that was cured at 180°C with high-quality epoxy resin. In addition, a functionalized surface layer of polyetherimide (PEI) was applied. The stiffening ribs were printed using Weber’s DXR system, which created a stable bond between the ribs and the base part.

Topology optimization techniques enabled a design of the part that optimized strength and weight. By using Dassault Systèms’ 3DEXPERIENCE platform, initial analysis was performed to evaluate performance and structural integrity.

Since 2019, the WEBER additive division has been an integral part of Hans Weber Maschinenfabrik in Kronach. With its many years of experience in the construction of plastic extruders as well as wood and metal grinding machines, the machine factory offers ideal conditions for the development and production of additive manufacturing systems.

Additive manufacturing is revolutionizing the manufacturing industry with digital 3D design data that can produce complex and large-volume components quickly and cost-effectively with low material input. Hans Weber Maschinenfabrik is the only German manufacturer to offer in-house developed robotic manufacturing systems, gantry systems as well as hybrid systems.

The results of the project, the shuttering demonstrator, can currently be admired in various exhibitions, most recently at JEC 2023 in Paris. Hans Weber Maschinenfabrik continues to focus on innovative developments and customized solutions to fully exploit the possibilities of additive manufacturing.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.