How do you actually clean the many delicate components of a mechanical wristwatch? There are special cleaning machines for professionals, but they are very expensive. Maker David Burke therefore came up with a clever idea: he used an older 3D printer and converted it into an automatic watch cleaner.

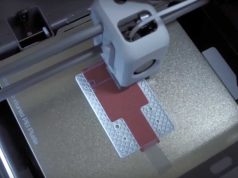

The basic principle is very simple: the machine runs through several stations for cleaning, rinsing and drying, with the watch being transported through the printer in a basket. Instead of a print head and extruder, Burke has installed a holder with a motor and spindle to which the watch basket is attached.

Modified firmware based on Klipper is used for control. Only the retrofitted drying heater caused some work, as it was incorrectly recognized by the system as a printer heating bed. However, this problem could also be solved with direct control.

His detailed instructions can be found on Instructables and the watch cleaner can be seen in action here:

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.