Infill patterns have an important function in 3D printing. They give printed objects an internal structure without adding much material and weight. The YouTube channel Slant 3D has done a comprehensive analysis of common patterns in a video.

3D printing makes it possible to create seemingly hollow objects. Infill rates of 10 to 25 percent are common, as the outer shell provides most of the strength. A wide variety of patterns exist, offering different properties.

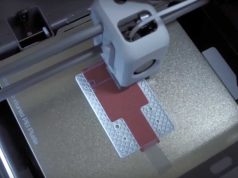

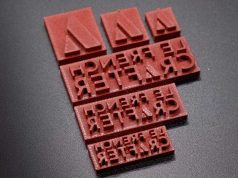

In one experiment, Slant 3D examined all of the standard infills in the Cura software. Parts were printed with 25 percent infill of PLA and then compressed. How and where the structures break was observed.

According to the results, simple grid and triangle patterns show the most controlled fracture behavior. Other variations, such as zigzag, are more prone to layer-by-layer breakage. The video illustrates how the choice of infill specifically influences strength and fracture dynamics.

For the majority of applications, Slant 3D recommends standard grids or triangles because they offer the best balance of material and reliability. However, knowledge of the particular fracture characteristics helps to optimize infills specifically for certain mechanical loads.

You can watch Slant 3D’s insightful video here:

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.