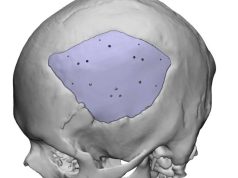

British researchers have developed a method for manufacturing prostheses using 3D printing. According to Loughborough University, prostheses for leg amputees could soon be produced on site in hospitals or even at home.

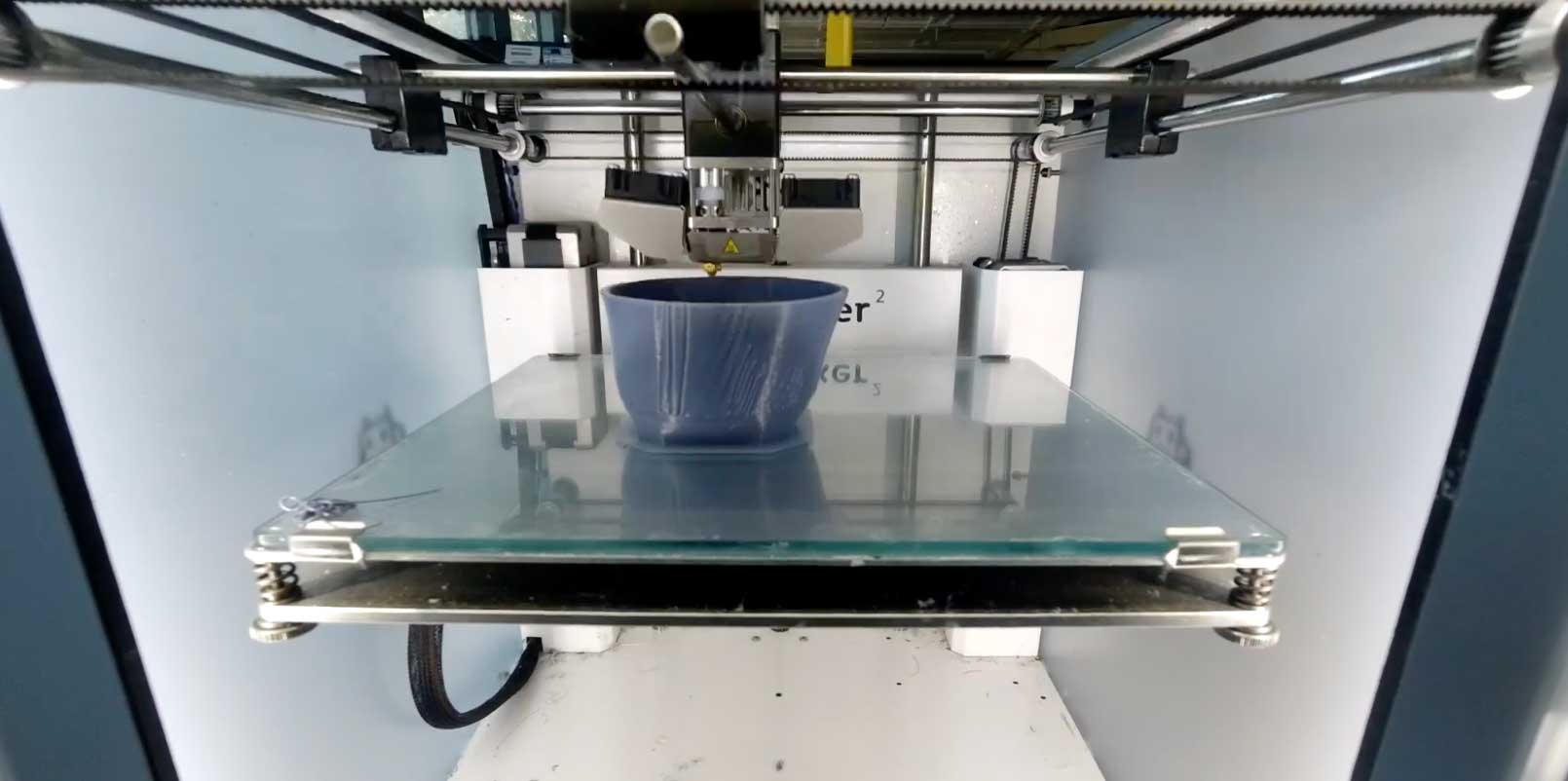

Using modern 3D scanning technologies and special software, body measurements can be taken precisely. This is used to generate an individual design profile that can be output directly to a 3D printer for production.

In contrast to time-consuming manual production, this digital process takes just 8 hours. In addition, minimally invasive adjustments to the fit are possible without having to make a new mold, which increases comfort.

According to project manager Simin Li, decentralized 3D printing capacities could significantly improve the provision of prostheses in the future, especially in regions that are difficult to reach. Healthcare professionals would then only have to check the body scan and approve the design so that patients can print their custom-made prosthesis locally.

Loughborough University sees great potential in computer-manufactured medical technology to decentralize and massively improve healthcare for the disabled, even in less developed countries.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.