A research proposal by Benay Gürsoy, assistant professor of architecture at PennState, has been awarded nearly $50,000 as a recipient of the Stuckeman School’s Collaborative Design Research Fund 2023-24, which supports collaboration in design innovation.

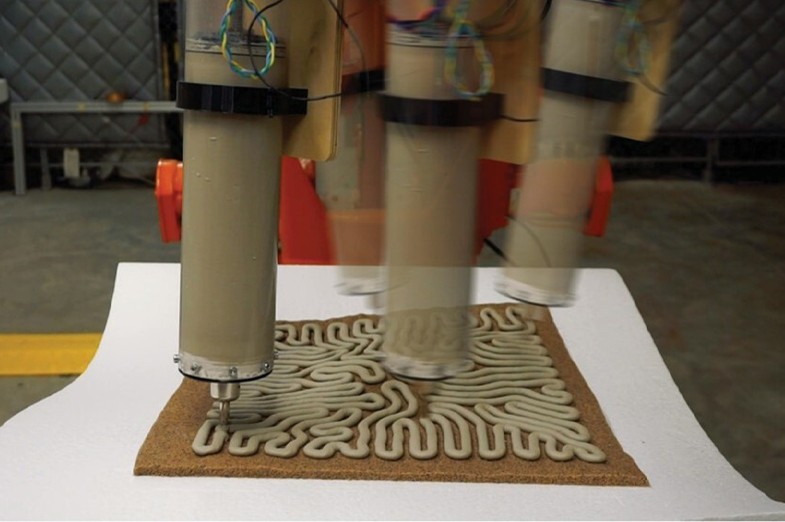

The goal of the project is to overcome the challenges of 3D printing concrete structures to reduce the environmental impact of residential construction. Gürsoy, who is also director of the Form and Matter (ForMat) Lab in the Stuckeman Center for Design Computing (SCDC), is working with an interdisciplinary team from the College of Arts and Architecture’s Stuckeman School and the College of Engineering to achieve this.

However, the precision and control offered by robotic arms in the production of concrete structures reach their limits when it comes to sensing and reacting to the environment. In their proposal, the ForMat Lab team – in collaboration with the Additive Construction Lab (AddConLab) and the Control and Autonomous Robotics Lab (CARL) – will digitally scan and reconstruct the robot’s working environment. This will initially take place in small robot-assisted production applications and will later be applied to large-scale concrete 3D printing processes. An important component of this system was developed by Özgüç Çapunaman, a researcher in the ForMat lab and a PhD student in architecture, as part of his doctoral thesis.

The project, titled “A Vision-Based Sensing Framework for Adaptive Robotic Additive Manufacturing of Concrete on Indefinite Surfaces and Real-Time Monitoring of the 3D Printing Process”, is also a central part of the PhD thesis of Paniz Farrokhsiar, a member of the ForMat Lab and the AddConLab. It expands on her master’s thesis, which she completed in 2020 under Gürsoy’s supervision.

“Concrete is one of the most widely used construction materials globally and contributes up to 8% of global carbon dioxide emissions,” explained Farrokhsiar. “By 3D printing concrete, we can reduce construction time and waste, which is more sustainable than conventional practices. However, the 3D printing process brings about critical challenges that affect the structural stability and the quality of the 3D-printed concrete structures.”

According to the researchers, the developed system will enable precise digital reconstruction and registration of the working environment prior to robotic tool operations. It will allow 3D printing of concrete on indeterminate surfaces, real-time monitoring of the 3D printing process, real-time adjustment of the system for error correction and shapeless 3D printing. This system is an important contribution to the AddCon Lab’s ongoing effort to develop means to automatically monitor and control the concrete printing process.

Principal investigators involved in the project are José Pinto Duarte, director of the SCDC and Stuckeman Chair in Design Innovation, Sven Bilén, professor of engineering design, electrical and aerospace engineering, and Donald Ebeigbe, assistant professor of electrical engineering and director of CARL in the School of Electrical Engineering and Computer Science.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.