3D printer manufacturer Formlabs has introduced the new Silicone 40A Resin Material, the first pure silicone material available for Form 3D printers.

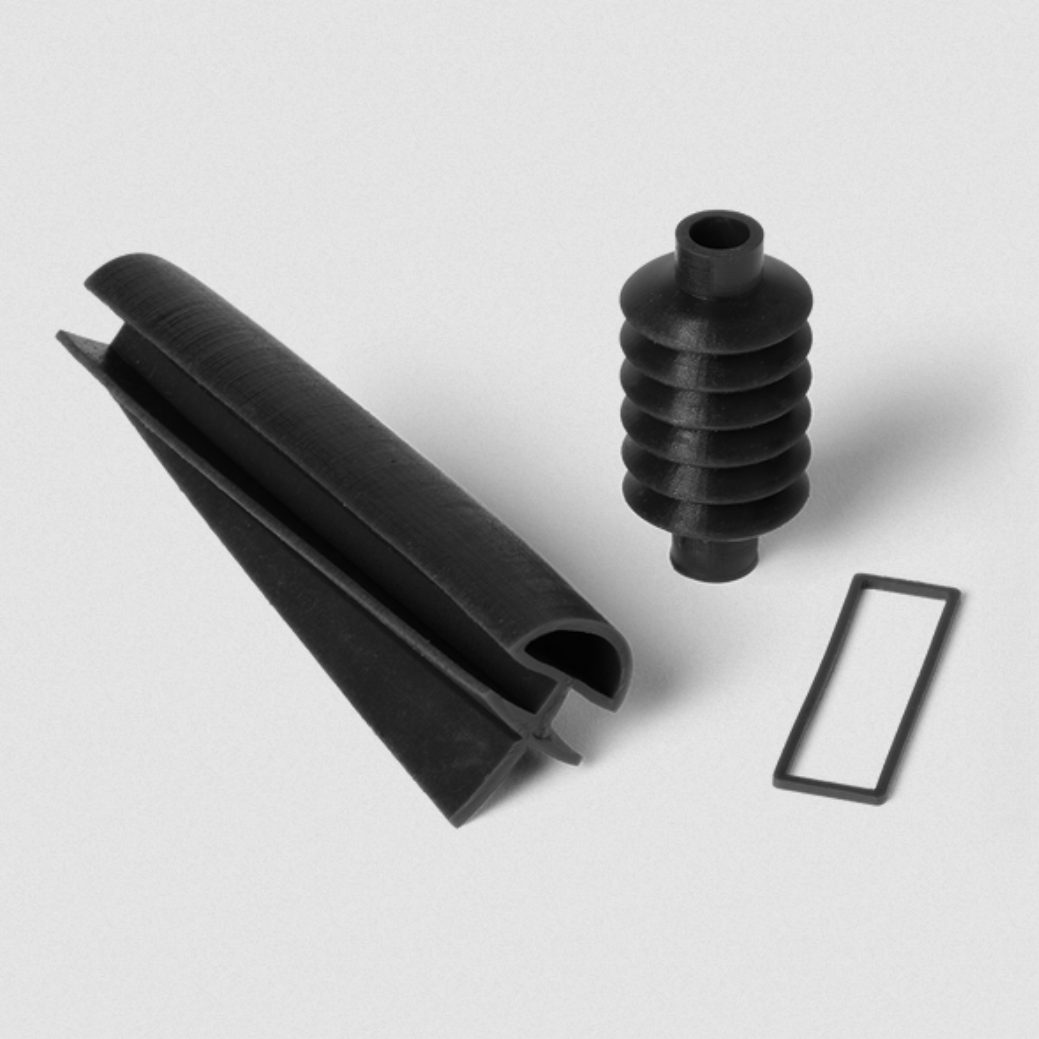

The 40A Shore resin material makes it possible to produce soft, pliable and durable parts with an elongation of 230% at break and a crack resistance of 12 kN/m, which can withstand repeated stretch, bend and compression cycles. The resin thus offers the high-performance properties of silicone, coupled with the design freedom of 3D printing, to create highly functional silicone parts. These feature excellent chemical and thermal resistance (-25°C to 125°C), fine detail down to 0.3 mm, and complex geometries not possible with traditional methods.

Currently, Formlabs is awaiting TSCA registration, without which the resin can only be used for research purposes. The expectation is that registration will be completed by the end of 2023.

So why Silicone 40A Resin?

It combines the benefits of silicone with the advantages of 3D printing, enabling cost-effective rapid prototyping and low-volume production and offering unique design opportunities. With Formlabs’ streamlined SLA ecosystem, pure silicone parts can be quickly and easily produced in-house.

Silicone 40A Resin is versatile in applications such as gaskets, wearable devices, custom prosthetics and flexible fixtures. It offers an effective solution for functional prototypes and small batches of silicone parts in various industries such as consumer goods, automotive, robotics and healthcare.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.