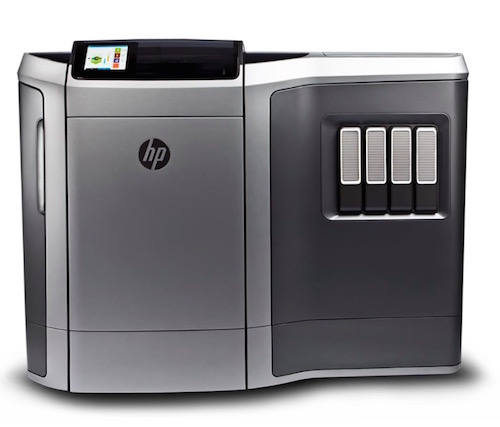

The long awaited and rumoured entry in the 3D printing market form HP is finally here.

October 30, 2014: Today Hewlett Packard announced their new 3D printing technology. Multi Jet Fusion is said to be faster and cheaper than other existing technologies. The technology builds on HP´s 2D printing inkjet technology. It drops small amounts of colour and glue on a powder. After that thermal heating systems hardens the materials.

How the new technology works:

As with many 3D printing processes, HP Multi Jet Fusion TM technology starts by laying down a thin layer of material in the working area. Next, the carriage containing an HP Thermal Inkjet array passes from left-to-right, printing chemical agents across the full working area. The layering and energy processes are combined in a continuous pass of the second carriage from top-to-bottom. The process continues, layer-by-layer, until a complete part is formed. At each layer, the carriages change direction for optimum productivity.

Using HP Thermal Inkjet arrays with their high number of nozzles per inch, HP’s proprietary synchronous architecture is capable of printing over 30 million drops per second across each inch of the working area.

Here are a view videos explaining how HP´s Multi Jet Fusion Technology could change 3D printing:

January 7, 2015: Update HP Multi Jet Fusion Technology will be powered by Intel

HP and Intel announced their cooperation for HP’s Multi Jet Fusion System at the International CES in Las Vegas this week.

The Intel Core i7 processors will be integrated into HP Multi Jet Fusion technology and used in product testing with customers throughout 2015. The official distribution of the HP 3D printer will start in 2016.

Dion Weisler, Executive Vice President, Printing & Personal Systems: “HP Multi Jet Fusion is uniquely designed to resolve fundamental limitations in today’s 3D printing technologies with the potential to revolutionize manufacturing. In order for 3D printing to reach its full potential, we not only need the most powerful processors, but a technology partner with a shared vision for the industry.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.