Lithoz GmbH, a provider of ceramic 3D printing solutions, has revealed all details about their all-new CeraMax Vario V900, which will be launched at the coming ceramitec (21-24th June).

The innovative machine can produce large ceramic components with thick walls and full densities using oxide and non-oxide ceramics. It can also process dark ceramics such as silicon carbide. This latest advancement not only fills an important market gap, but also marks the beginning of a new era for Lithoz.

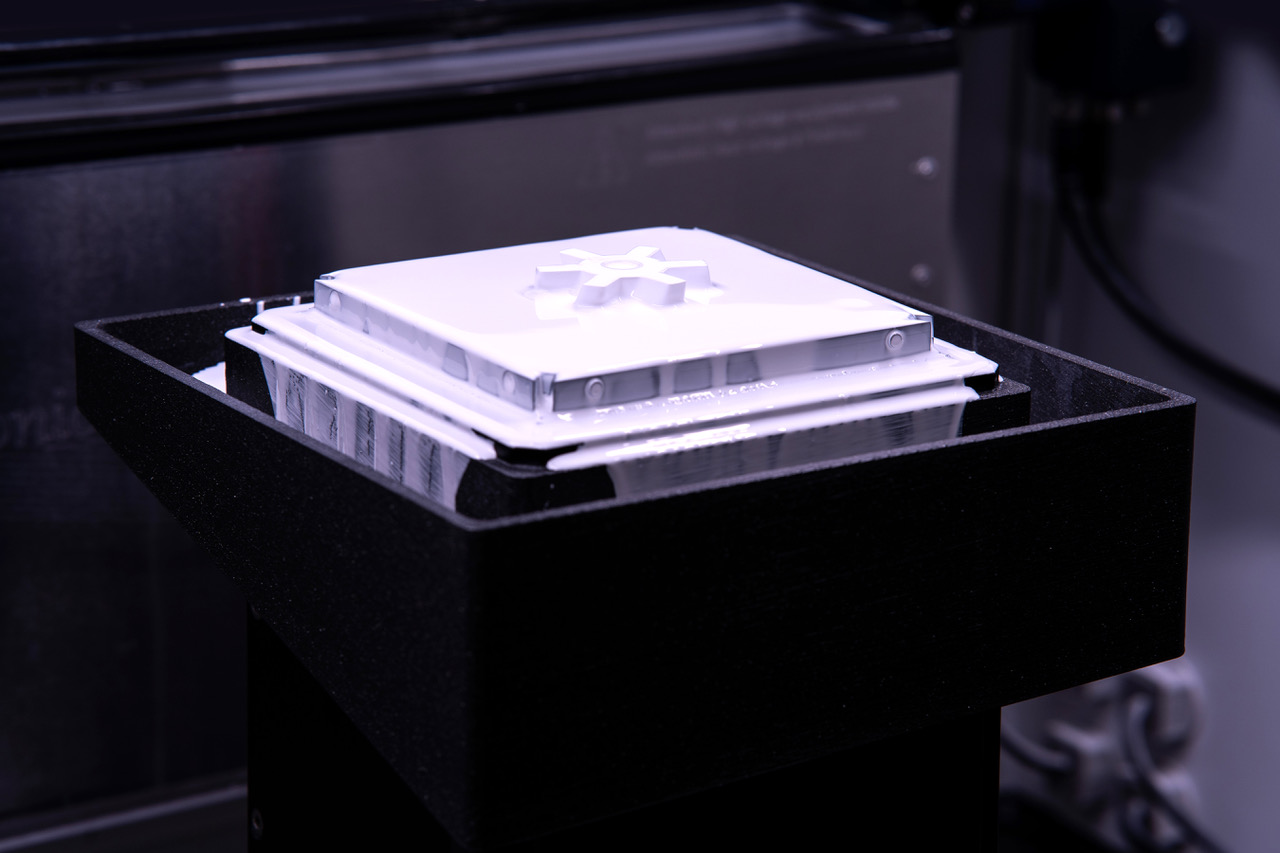

With the ability to apply up to 1.000 μm slurry per layer in less than a minute and a building envelope of up to 250 x 250 x 290 mm, the CeraMax Vario V900 uses innovative Laser-Induced Slipcasting (LIS) technology, enabling additive manufacturing using industrial water-based suspensions with very low organic binder contents. Thanks to the much-simplified debinding process, wall thicknesses can be realized that, according to Lithoz, has not yet been possible in other ceramic 3D printing technologies.

Green parts printed with the CeraMax Vario V900 are machinable without any restrictions, meaning they can therefore be easily reintroduced into the traditional ceramic process chain. For ceramic producers, LIS technology is the ideal technological entry point into ceramic 3D printing, as it perfectly combines the full 3D design flexibility plus a considerably accelerated ceramic shaping process with economical water-based suspensions which stay very close to familiar standards slurries.

In the LIS technology powering the CeraMax Vario V900, the water-based slurry solution completely absorbs the laser beam. Due to treatment being purely heat-induced, even dark ceramics such as silicon carbide can be processed without issues or loss of desired properties. Silicon carbide, one of the most sought-after technical ceramics for both mechanical properties and width of possible applications, is notoriously difficult to process via any additive manufacturing technology that involves the use of light for curing slurry materials. The new LIS technology finally opens the door to the processing of this innovative material.

A central element of the CeraMax Vario is the database-supported storage and management of all process data, enabling seamless documentation of print jobs. Optional software upgrades allow for even better parameter control or adjustment, as well as the structuring of your production data and the possibility of real-time process monitoring via remote video transmission.

As of now, the brand-new LIS technology employed in the CeraMax Vario V900 will complement Lithoz’s product portfolio. The company’s market-leading Lithography-based Ceramic Manufacturing (LCM) technology will remain the number one choice for realizing complex structures, ultra-precise details or thin walls. LIS fills another important market area and will take on the role of 3D printing larger ceramic parts while still maintaining all desired ceramic properties.

(c) Picture & Link: www.lithoz.com

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.