The cosmetics company L’Oréal has been researching innovative skin models since the 1980s. In collaboration with Professor Paul Dalton from the University of Oregon, a breakthrough has now been achieved: the development of a new type of multi-layer skin model using a special 3D printing process.

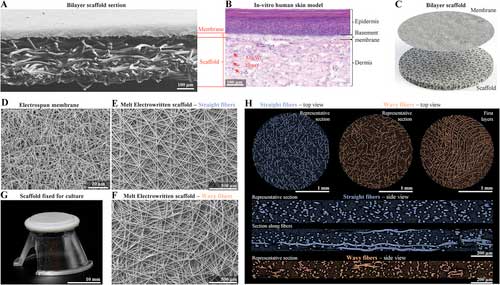

The special feature here is the realistic reproduction of the natural skin structure. Using the MEW (Melt Electrowriting) printing process, extremely fine fibers made of a biocompatible plastic are woven into a porous scaffold structure. This scaffold then forms the basis for the growth of human skin cells in separate layers – similar to the structure of real skin.

“Other approaches do not achieve such realistic layering,” explains Professor Dalton, whose laboratory co-developed the MEW process. The complex tissue structure can be precisely mimicked by specifically controlling the fiber sizes, arrangements and porosities.

The L’Oréal researchers cultivate fibroblasts and keratinocytes – two key cell types in the skin – on the basic scaffold. Certain factors, such as the addition of vitamin C, accelerate tissue formation to just 18 days.

The resulting two-layer skin models with realistic texture and elasticity are intended to facilitate product testing and advance research into skin diseases and therapies. Personalized skin substitutes for burn victims are also conceivable.

This skin model was developed in collaboration between L’Oréal’s Advanced Research teams and Professor Paul Dalton of the Phil and Penny Knight Campus for Accelerating Scientific Impact at the University of Oregon. Their research was published in the journal Advanced Functional Materials under the title “First Advanced Bilayer Scaffolds for Tailored Skin Tissue Engineering Produced via Electrospinning and Melt Electrowriting“.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.