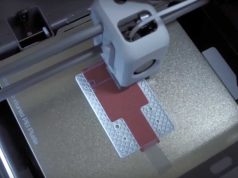

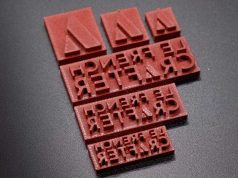

A resourceful maker named “Fraens” has developed a 3D-printed braiding machine – the first working DIY solution of its kind. He was inspired by the traditional Japanese braiding technique Kumihimo. Instead of avant-garde design, he uses common 3D printed components to build an efficient machine.

Last year, Fraens presented a first prototype with 6 coils. Now it has been further developed into a sophisticated model that can even weave 12 ropes simultaneously thanks to a powerful geared motor. Through clever design, the ropes are kept under tension at all times, resulting in neat braiding patterns.

According to Fraens, the project presents some technical challenges. For example, factors such as rope tension, drive force and braiding speed must be coordinated. Small changes can have big effects because of interactions.

By sharing his experience, Fraens hopes to encourage others to explore the possibilities of 3D printing. His braiding machine is an impressive demonstration of how patient development work and simple tools can create impressive solutions. Fraens makes the print data and build instructions available at Cults3D.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.