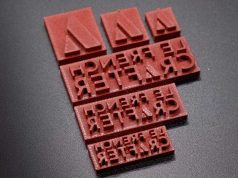

A new method for smoothing the surface of printed parts is gaining popularity in the 3D printing community. This involves applying a mixture of UV resin and baby powder to the printed objects. This smooths out the typical layer lines of 3D printing and creates very uniform surfaces.

As YouTuber DaveRig demonstrates in a video, the technique is particularly suitable for larger, flat surfaces. In his test, he first printed a dome with striking layer lines at a height of 3 mm using a Bambu Lab FDM printer. For this object, he uses the hack for post-processing. After applying and curing the resin-powder mixture under UV light, the lines were already significantly reduced. After repeating the process several times and then sanding, the dome was given a mirror-smooth surface.

According to DaveRig, the mixture consists of two parts UV resin and one part baby powder. The latter ensures that the resin spreads better and that the coats can be applied very thinly and evenly. Priming, varnishing and polishing further refine the surface.

The method allows for cost-effective smooth finishes without expensive industrial paint. However, DaveRig says care must be taken with intricate details to avoid clogging.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.