US-based Markforged has introduced updated versions of its H13 and D2 tool steel filaments for the Metal X 3D printer. According to the manufacturer, the new filaments feature higher flexibility and less brittleness.

According to Markforged, the new materials improve printer performance and enable new print modes in the future to cover even more applications. In addition, the filaments can now be used at room temperature, which reduces preparation time.

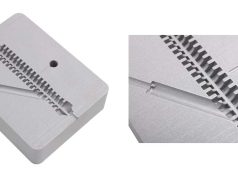

With a capacity of 400 cc, the new spools are said to hold twice as much material as before. As a result, filament changes are required less frequently. Markforged first launched the tool steel filaments in 2018 and has been able to use them in industrial applications such as metal molds, injection molds and hardened inserts.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.