Software developer Materialise announces e-Stage for Metal+ software. The software optimizes data and build preparation for laser powder bed fusion (LPBF) systems using physics-based modeling to automate the generation of support structures. This solution will be presented at the Additive Manufacturing Users Group (AMUG) in Chicago.

LPBF is leading the AM industry with over 52% of global revenue in 2022. However, it is considered one of the most complex technologies with many challenges. According to an independent survey commissioned by Materialise, a lack of knowledge and the costs associated with the production process are holding companies back from adopting 3D printing. These challenges are especially key in the preparation phase for LPBF.

“By automating support structure generation with Materialise’s software, you can streamline your 3D printing process,” says Mirco Schöpf, Product Line Manager Software at EOS. “It simplifies support removal, reduces support volume up to 80%, eases powder extraction, and decreases build plate machining after an effortless part removal. We look forward to exploring e-Stage for Metal+ and discovering additional benefits.”

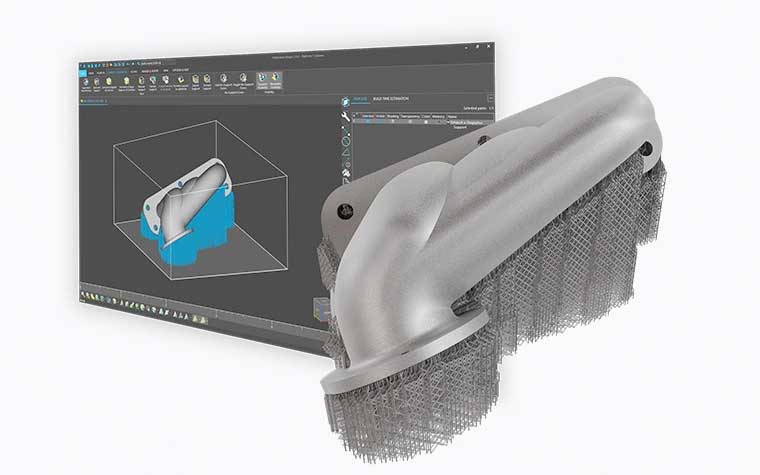

e-Stage for Metal+ uses physics-based modeling to calculate deformations during the 3D printing process and automatically generate needle-thin and tapered supports where they are needed. The combination of both support types optimizes stability and heat distribution during the 3D printing process, helps to avoid partial deformations and reduces post-processing efforts. This allows companies to balance quality and production costs by making the entire LPBF process more economically attractive and easier to use.

“Metal AM users tend to overload parts with support structures during manual data preparation,” explains Ian O’Loughlin, Metal Practice Lead at Materialise. “They want to avoid defects and the costs associated with reprinting the parts. That’s why intelligent tools like e-Stage for Metal+ are crucial. Automating support structure generation at the sweet spot of printability and required supports saves time, material, and post-processing costs.”

e-Stage for Metal+ is a module for Magics, Materialise’s leading data and build preparation software and a core part of its 3D Print Suite. Magics is a technology-neutral software that is compatible with virtually all import file formats and offers connections to all major 3D printing technologies. It gives users advanced control and automation of their workflows.

“We are continuously enhancing our software solutions to support AM users in their daily business,” says Lieve Boeykens, Solution Strategist at Materialise. “Automation can support AM users in bridging knowledge gaps to adopt the technology faster, accelerating return-on-investment, and helping them lower the overall production cost. Materialise’s e-Stage for Metal+ helps companies achieve economic viability.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.