British company Mayku has introduced an enhanced version of its Multiplier desktop pressure former. According to the manufacturer, the device now achieves such high precision that it can be used to produce small batches of production parts.

The Mayku Multiplier uses pressure and heat to shape thin plastic sheets. Until now, it has been used primarily for prototypes and small batches. However, a new “custom mode” function for individual material profiles and expanded control options should now make it possible to produce series parts with injection molding-like quality.

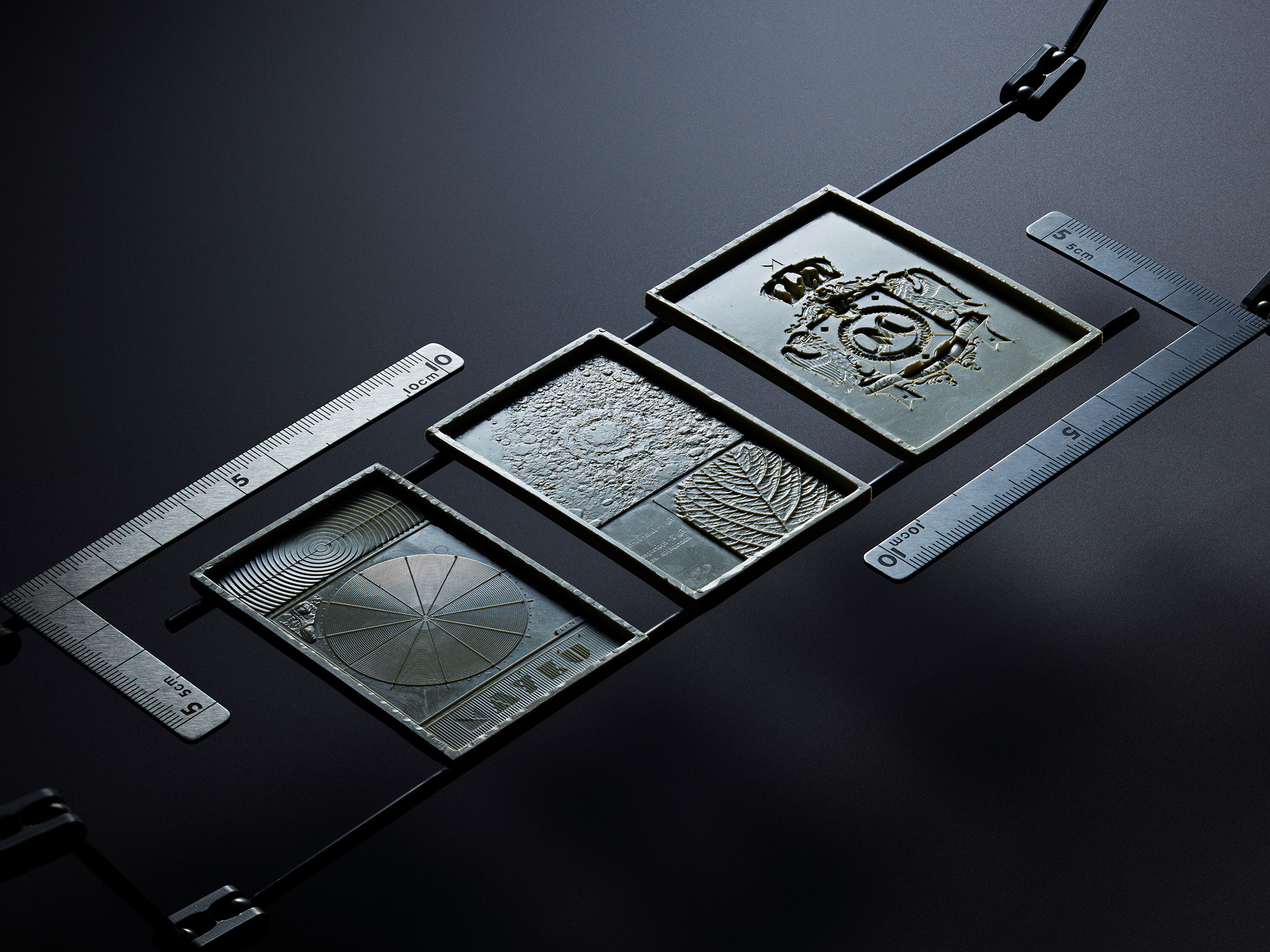

According to Mayku, surface details in the sub-micrometer range and very short cycle times of 2 to 30 minutes are possible. Customers in fields such as product design, medicine and robotics are using the pressure former to cost-effectively produce small quantities of robust and chemically resistant parts.

New accessories also enable processing ofstandard material formats. Mayku aims to bridge the gap between prototyping and low-volume production with the high-performance desktop device. It is designed to combine the advantages of 3D printing with the precision and series capability of injection molding.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.