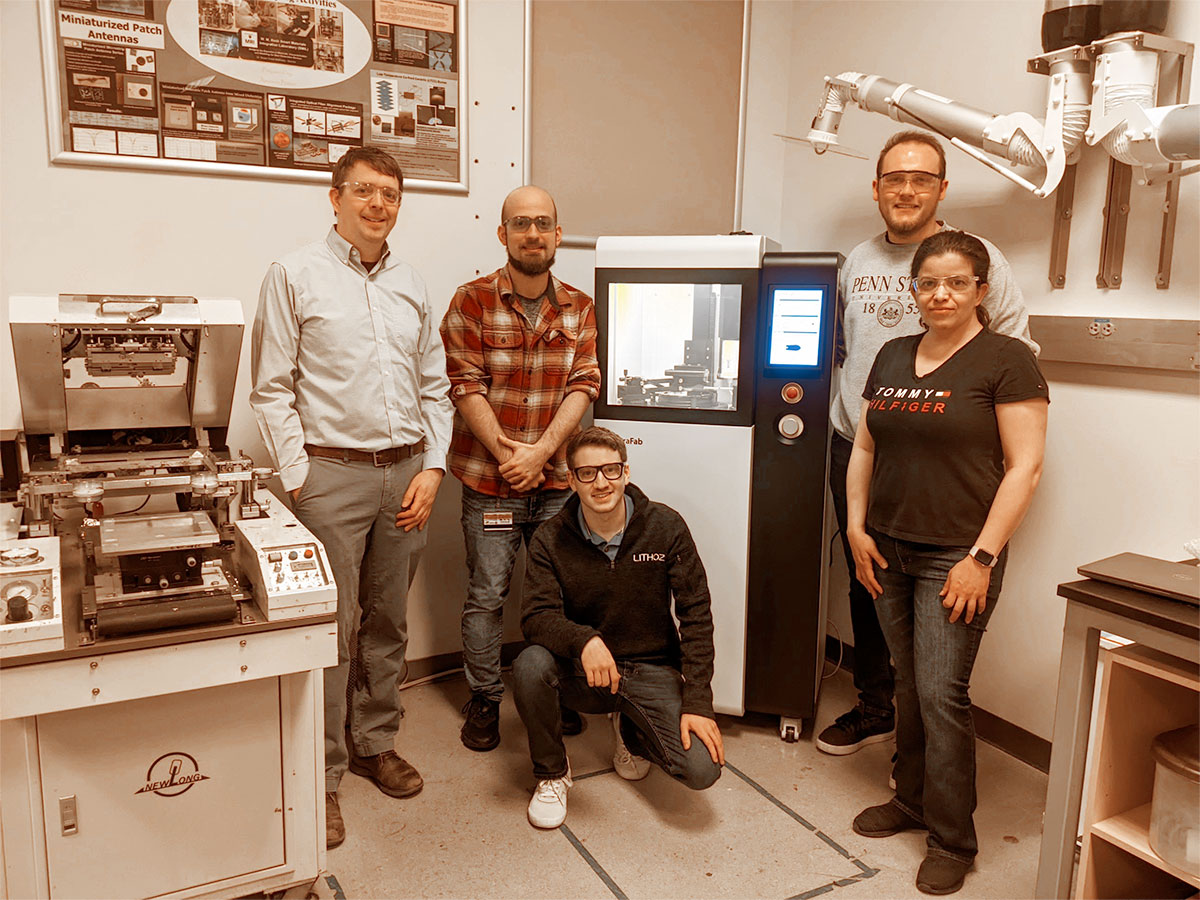

A recently installed 3D ceramic printer provides Penn State materials researchers with advanced capabilities to easily produce high-resolution ceramic parts and other ceramics for materials research.

“This will be part of a user facility here at Penn State, in the Nanofabrication Lab,” said Amira Meddeb, associate research professor in MRI. “The number one reason we acquired it is to allow more capabilities not just for the Penn State community but also for our extended user community that we work with, including other higher education institutions and industry.”

This production capability also allows MRI to produce custom scientific instruments for other Penn State researchers that are normally expensive and difficult to obtain.

The resin-based printer uses digital light processing technology, a technique that cures light-sensitive liquid resins into hard solids. This enables in-house production of high-resolution parts and full-density ceramics with properties and microstructure comparable to ceramics produced by conventional manufacturing methods.

“The printer allows us to produce custom and complex parts that are usually costly and have long lead times, such as custom-designed crucibles and microreactors,” Meddeb said.

“Ceramics are extremely hard to manufacture traditionally for a variety of reasons, especially because they’re so hard when they’re finished and sintered, they’re very difficult to machine,” said Shawn Allan, vice president of Lithoz America LLC. “In addition, they can be delicate before they are sintered so in that state, they are also hard to fixture and machine. Versus with this printer, you can much more easily make multiple iterations of a part with different geometries and different dimensions and get the actual part you need.”

The printer can print a variety of ceramic materials. It offers the ability to easily switch materials for different projects, and its operation is relatively easy to learn, especially for someone with a traditional background in ceramics processing. The printer rounds out MRI’s research offerings, according to Chad Eichfeld, associate research professor and nanofabrication lab operations manager.

“Penn State is a hands-on educational institution,” Eichfeld said. “At other universities, a student might give some of the processing that is done in Amira’s lab and my lab to a technician, and they would do the work for you. But we are all hands-on. That is powerful, with our graduate students and even some undergraduates getting hands-on experience with state-of-the-art technology here. That experience will be really rewarding for them as they begin their career.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.