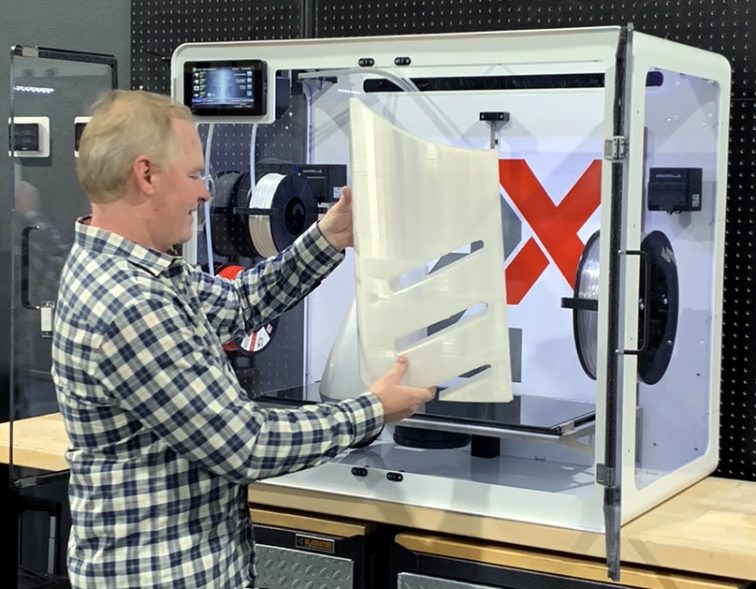

US manufacturer Airwolf 3D has introduced EVO 2X, a new, large FDM 3D printer. The printer is said to be compatible with many materials and has a large build envelope of 61 x 30 x 56 cm.

Airwolf 3D’s latest creation, the EVO 2X, allows enthusiasts and professionals to produce colossal prints with a variety of materials including ABS, polycarbonate, nylon, HydroFill Water-Soluble Support and over 40 other 3D printing materials. The EVO 2X builds on the impressive size of the EVO printers, offering nearly double the print volume of Airwolf’s previous largest printer, the EVO 22. Energy-efficient heating systems allow the EVO 2X to maintain the heating chamber at over 70 degrees Celsius while maintaining a large heating bed for optimal part adhesion – a constant throughout the EVO product line.

“What separates our machines from the rest?” asked Airwolf 3D Co-Founder and CEO Erick Wolf. “We use EVO 2X printers to manufacture full-scale automotive bodies using 100% ABS. This is simply not possible with any other printer in this price range. Prints times range from 40 to 120 hours for each plate, demanding strong and reliable equipment. These large-scale parts showcase not only spectacular print quality but also display the necessary strength and mechanical properties for functional prototypes and end-use parts.

Other machines in the market lack this level of performance and quality, either because they can’t sustain the temperatures needed for engineering-grade materials, or because they compromise on construction, which isn’t sufficient for advanced industrial desktop manufacturing. With EVO 2X you do not need to buy overpriced specialized filament to make large parts. We designed the machine to handle readily available engineering-grade materials.”

The heated environment consists of two heating chambers and a high-temperature pressure bed that gives the user excellent control over the machine’s internal ambient temperature. This feature enables the creation of an ideal thermal setting for the production of large parts from engineering materials by increasing part strength and reducing defects such as cracking and warpage.

Continuing the legacy of the original EVO, the EVO 2X incorporates Airwolf 3D’s proprietary GENESIS board, an automotive-grade 32-bit microcontroller designed for higher speeds, precision and control at high temperatures, outperforming any other desktop 3D manufacturing system. In addition, the EVO 2X plugs into a standard household 3-pin outlet, so no special power connections are required.

“With the design of the original EVO, we ensured the technology was optimized and future-proof,” explained Wolf. “The EVO 2X embodies our commitment to continuous improvement, offering the best in industrial large part production with the convenience of a desktop form factor, including the added benefit of using a standard wall outlet.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.