A combination of physical printing process and digital blockchain technology can be used to map quality documentation in 3D printing in a transparent, traceable and tamper-proof way in a digital component file. This can increase trust in supply chains, improve the security of documentation data, and achieve intellectual property protection.

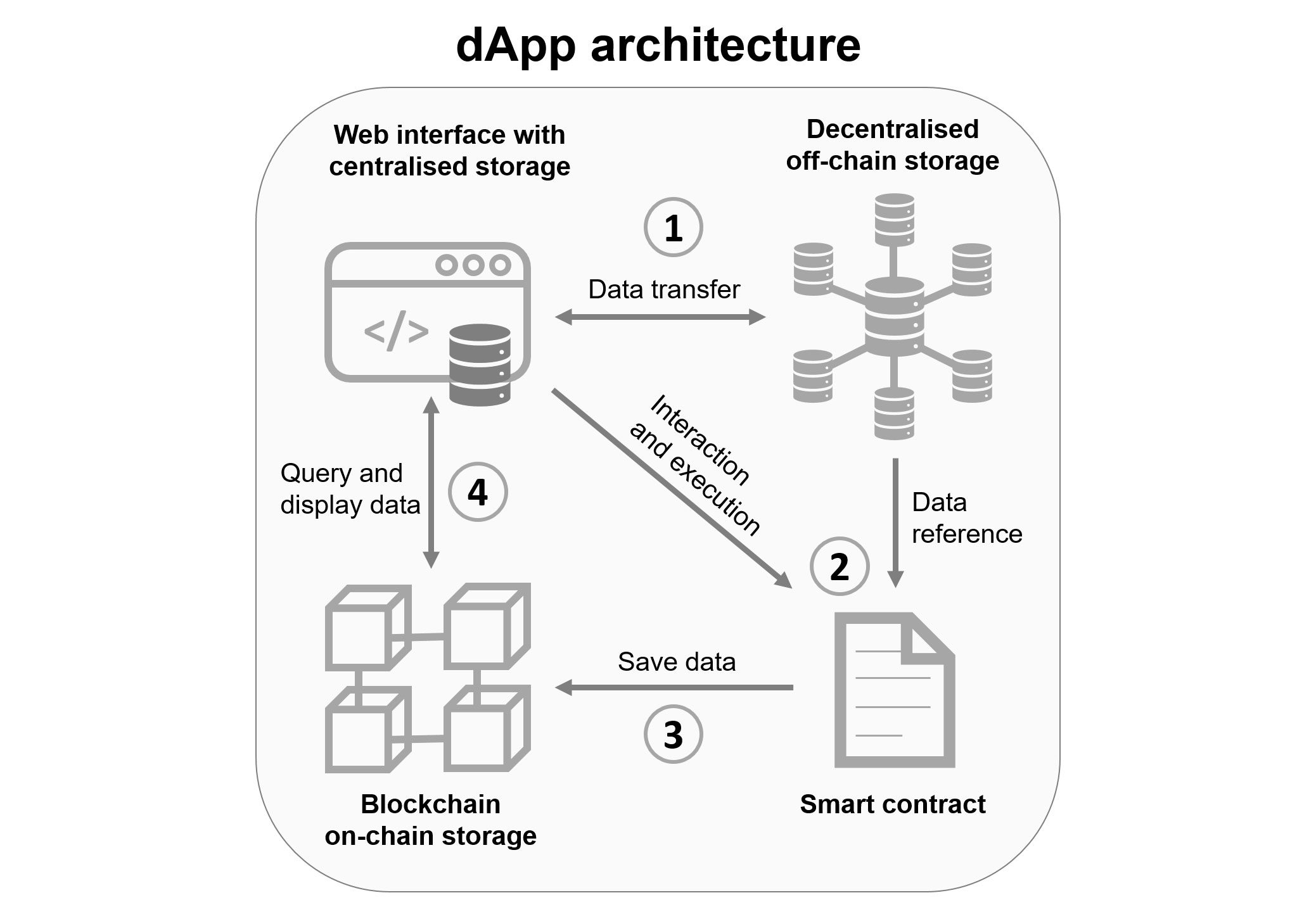

The secure, transparent and traceable documentation of quality-relevant aspects along the value chain of 3D printing processes is currently immature. There are no standardized solutions, especially with regard to the reproducible and legally compliant recording and storage of the resulting data. A decentralized software architecture consisting of digital data acquisition, a transparent and secure storage solution, and automated information processing controlled by algorithms linked to defined quality assurance processes can offer potential for improvement here.

Digital component file for 3D printed components

Researchers at the University of Rostock and Clausthal University of Technology have developed a corresponding solution in the form of a decentralized application (dApp), integrated it into the process flow of a complex 3D printing process and tested its basic functionality. This made it possible to map the entire 3D printing value chain in a digital component file in a transparent, traceable and tamper-proof manner, from the initial customer inquiry to the delivery of the component.

The research results illustrate the benefits of a blockchain-based 3D printing component file for digital manufacturing documentation and show an efficient alternative or extension option to existing quality assurance and documentation solutions in additive manufacturing.

The research was funded by the European Union and the state of Mecklenburg-Vorpommern. In addition, an SME also provided technical support for the research project. The research was carried out at the Chair of Microfluidics at the University of Rostock, where, under the direction of Prof. Dr.-Ing. Hermann Seitz, research is being conducted specifically on blockchain and artificial intelligence in additive manufacturing, among other things.

The researchers hope to enable fundamental impulses for industrial use with the prototypically implemented solution for a digital 3D printing component file. Titled “Blockchain-based quality management for a digital additive manufacturing part record” (DOI: 10.1016/j.jii.2023.100517), the entire results have been published open-source in a leading scientific journal.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.