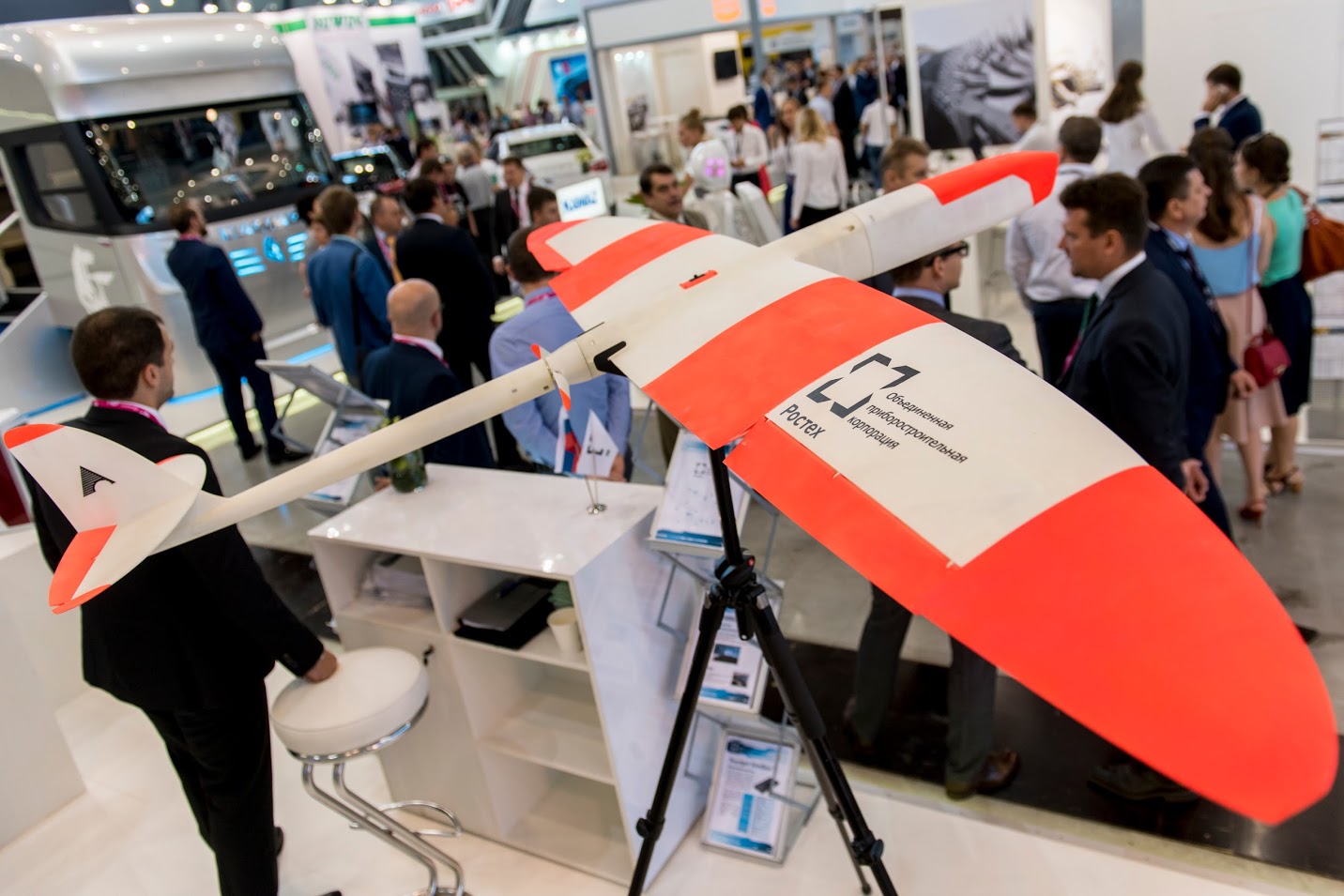

The Russian arms company UIMC has introduced their first 3D printed drone on an industry-fair in Yekaterinburg, Russia. The producer has also announced that the drone was already successfully tested and is able to fly.

It takes only one day to print all parts for the UIMC drone and only 15 to 20 minutes to build everything together. The finished plane has a weight of 4 kilograms. Only the electric components for the steering and propulsion are not 3D printed and have to be bought separately. It should be possible to mount different cameras ore sensors and measuring equipment onto the drone. But it was not told what’s the maximum payload of the airplane is.

Only a few weeks ago Airbus has presented its 3D printed drone, THOR. But THOR has more 3D printed parts and it takes more time to build it. Therefore the Airbus drone is much bigger and has a higher weight and a higher maximum payload. THOR has a size of about 4 times 4 meter and a weight of 25 Kilograms. More details to THOR are in our article to the drone.

Over all we can see that 3D printing already has its place in airspace industry. Not only for building prototypes it’s also used for different parts in real airplanes. Especially for small batches of parts or for very complex parts 3D printing has advantages and costs less than producing with conventional technologies.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.