According to a study by researchers at the University of Michigan, a new manufacturing process for spiral metal nanoparticles offers a simpler and cheaper way to rapidly produce a material important for biomedical and optical devices.

“One of our motivators is to drastically simplify manufacturing of complex materials that represent bottlenecks in many current technologies,” said Nicholas Kotov, the Irving Langmuir Distinguished University Professor of Chemical Sciences and Engineering at U-M and co-corresponding author of the study, published in Proceedings of the National Academy of Sciences.

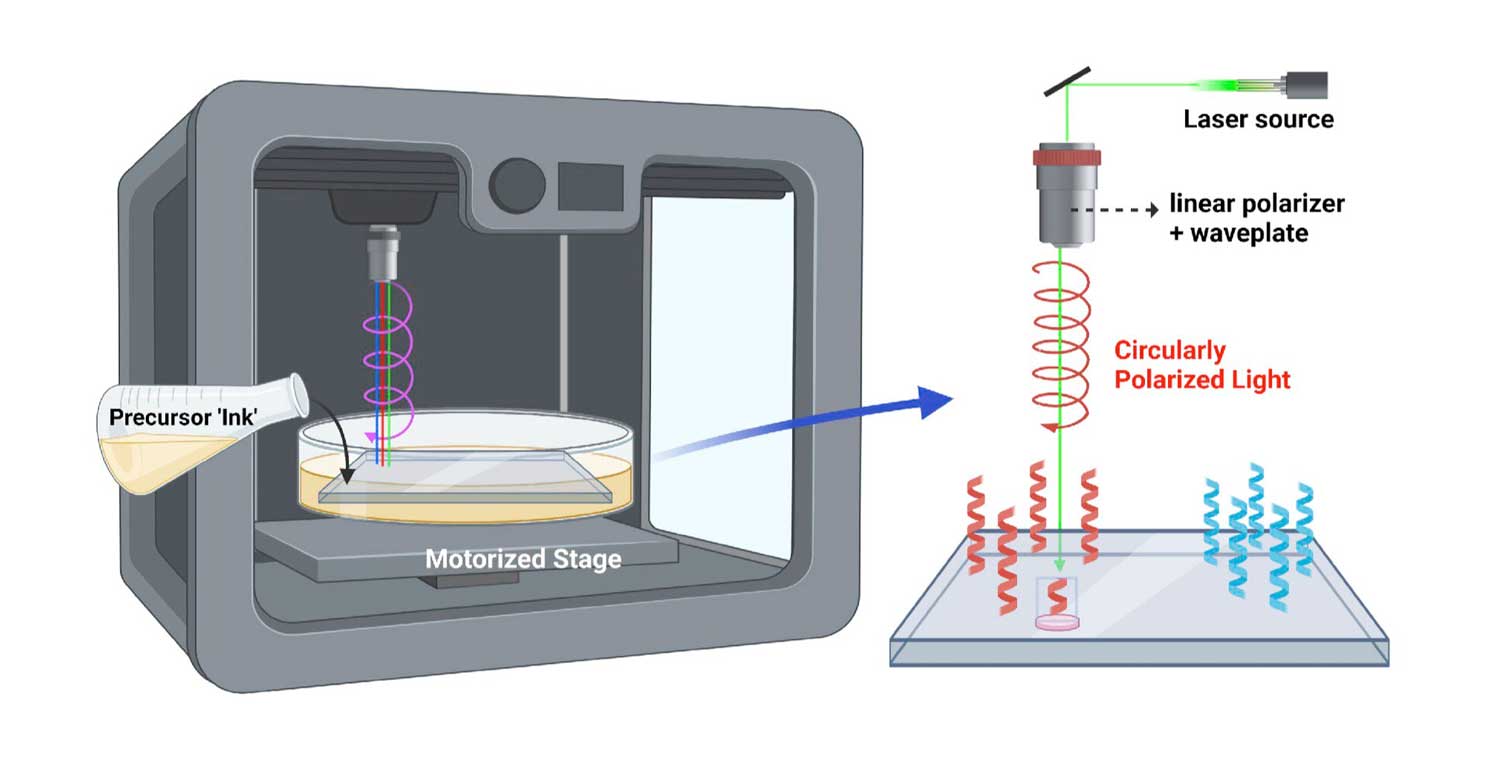

Chiral surfaces that have no mirror symmetry and can bend light on a nanoscale are in high demand. The study presents a method to produce such surfaces by 3D printing “forests” of nanoscale helices. By aligning the axes of the helices with a beam of light, a strong optical rotation is created, allowing chirality to be used in health and information technologies.

Plasmonic metals used to make chiral surfaces are particularly desirable because they can produce a large family of very sensitive biodetectors. For example, they can recognize specific biomolecules, which supports the development of targeted therapeutics. In addition, these materials offer potential for the advancement of information technologies by enabling greater data storage capacities and faster processing speeds.

Traditional methods for producing these special 3D-structured surfaces are complex, expensive and generate a lot of waste. The University of Michigan research group therefore developed a method that uses helical light beams to produce nanoscale helices with specific handedness and pitch.

“Centimeter-scale chiral plasmonic surfaces can be produced within minutes using inexpensive medium-power lasers. It was amazing to see how fast these helical forests grow,” said Kotov.

The ease of processing, high polarization rotation and fine spatial resolution of light-driven printing of metal helices will greatly accelerate the preparation of complex nanoscale architectures for the next generation of optical chips and represents a significant advance in 3D additive manufacturing.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.