Multitool 3D printers give architects even wider possibilities to quickly design, prototype and present their ideas in a tangible way.

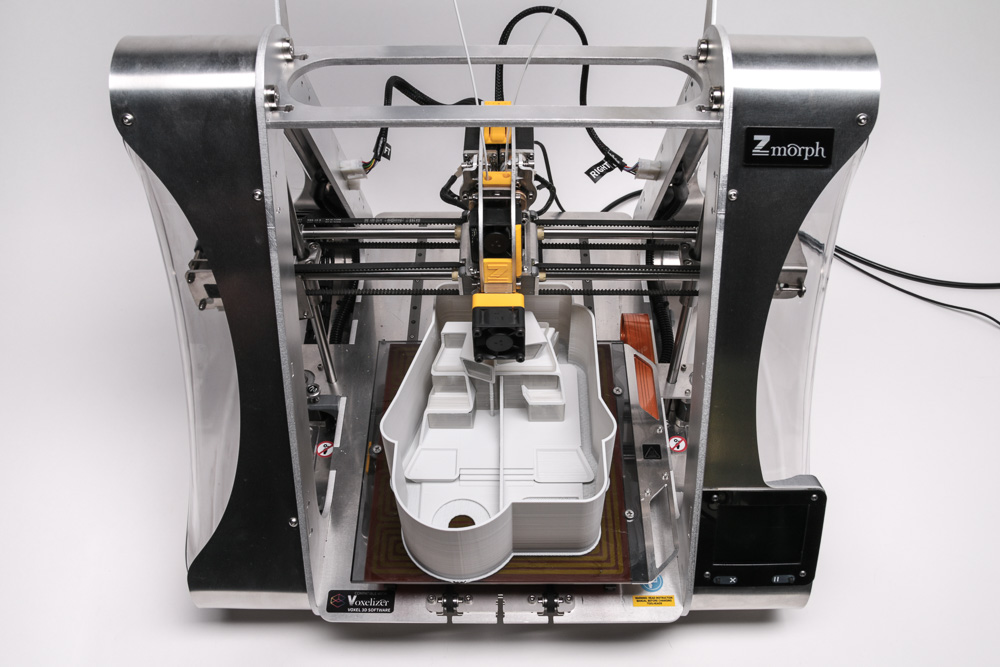

The latest ZMorph use case shows how a freelance designer, small architectural studio, or even a big company, can create a multi-material architectural model that’s both beautiful and useful. They just need a multitool machine that combines 3D printing, CNC milling, and laser engraving.

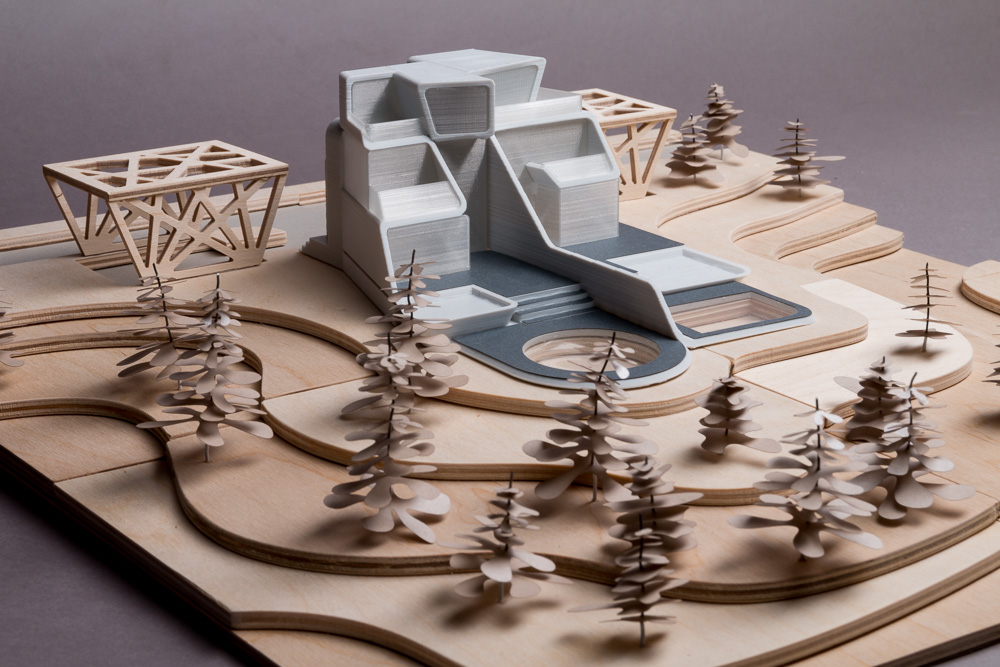

Inspired by the works of Zaha Hadid and her project studio, Paula Szarejko designed a futuristic house and its surroundings. ZMorph 2.0 SX gave her the ability to choose materials and manufacturing technologies that suited her ideas best. For example, she could 3D print the entire landform but decided that CNC-cutting it in plywood would have a much more organic and natural feel. Trees, on the other hand, were laser-cut in a paper for similar reasons.

The building was 3D printed using DUAL PRO which made it possible to manufacture the entire model in one piece. Gray PLA was used for walls while translucent PLA imitates glass. ZMorph 2.0 SX allowed her to shorten the production time and costs of 3D printing significantly while retaining a full control over the process.

90% of professionals who own a 3D printer consider it as their competitive advantage. With up to 75% lower production costs, the technology enables them to focus on creativity and new ideas instead of struggling with the limitations of traditional production processes. Multitool machines like ZMorph 2.0 SX enable architects and other professionals to achieve an even greater advantage over their competitors.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.