The Technology Innovation Institute (TII) has unveiled an innovative aluminum alloy called AMALLOY, developed specifically for the additive manufacturing process, at the AM Conclave conference in Abu Dhabi.

AMALLOY is the first metal substrate designed in the Middle East for laser beam powder bed fusion (PDF-LB) systems. This low-cost, high-strength aluminum powder exhibits excellent printability and performance.

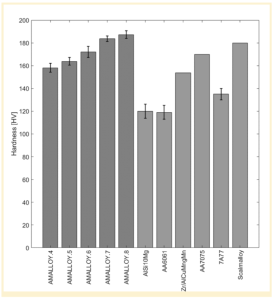

Compared to commercially available AlSi10Mg alloys, AMALLOY exhibits 33% higher strength without sacrificing ductility. These properties make it an ideal candidate for lightweight and high-strength parts in demanding applications.

AMALLOY features extremely low hot cracking susceptibility, which means higher strengths can be achieved without hot cracking. Such advances are possible through robust co-eutectic microstructure, saturation and grain refinement.

With the collaboration of Oxford University, atomic probe tomography (APT) analyses have revealed nanoprecipitates in the primary aluminum microstructure that further increase the strength of the alloy. In addition, the material shows excellent thermal stability up to 300°C, making it potentially applicable in high-temperature environments.

“Our focus is on developing high strength alloys with excellent printability. We intend to use these new materials in manufacturing defect-free parts to be employed in critical and high-value applications,” says Dr. Nesma Aboulkhair, Director of Additive Manufacturing at TII. “We are adopting a framework for an integrated computational and experimental approach to design and produce these new materials for use in metal AM. This framework constitutes six phases including alloy design, experimental validation, AM for in situ-alloying with accelerated process optimization, material testing, metal powder optimization, and finally, documentation.”

TII has filed a patent with the U.S. Patent and Trademark Office for AMALLOY and plans to use its framework to develop alloys from other metal families.

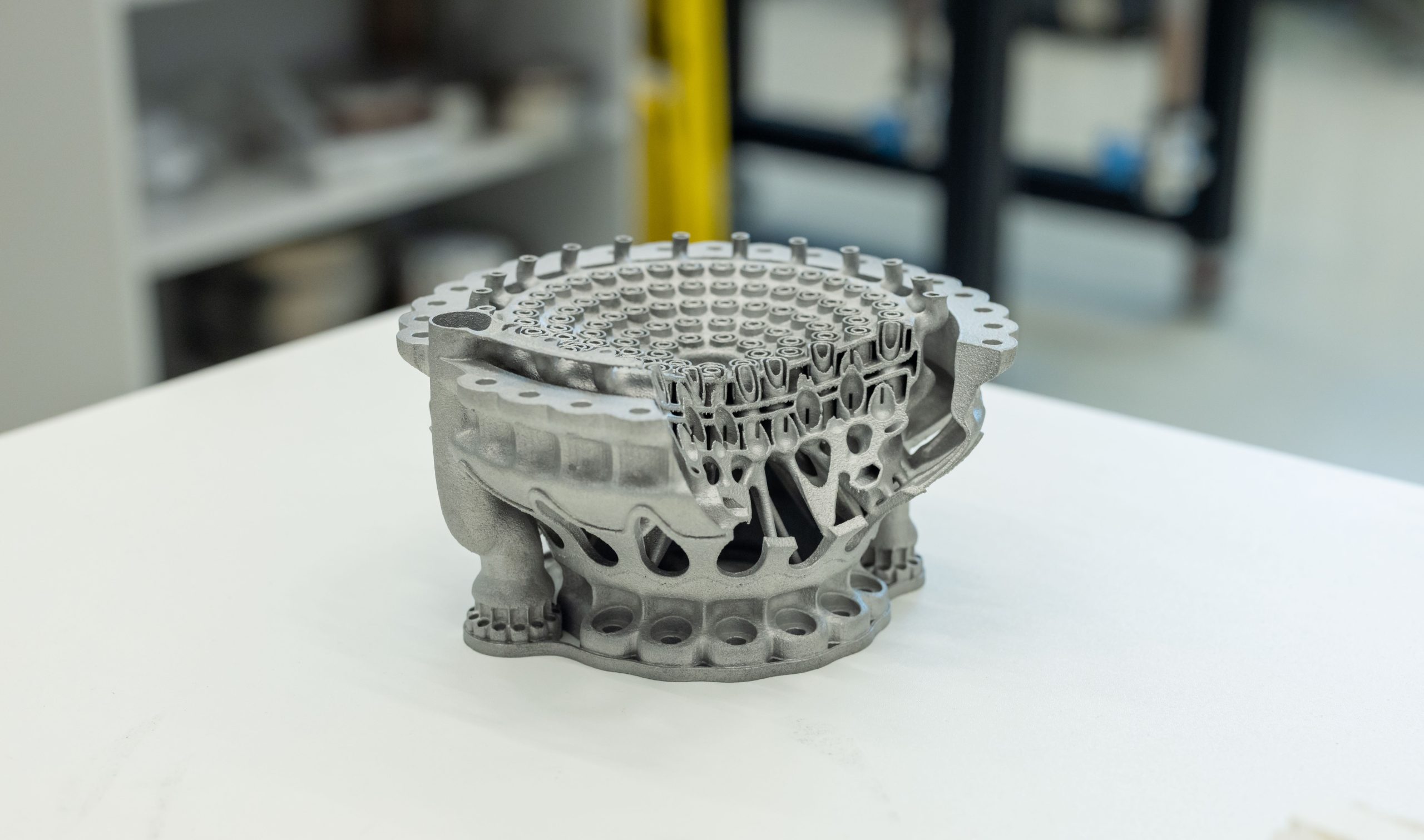

“The target clientiele for the new material we are developing for metal 3D printing are worldwide metal powder producers and we are exploring licensing our new patented alloy compositions to global manufacturers,” says Dr Federico Bosio, Lead Researcher for Additive Manufacturing Materials at TII. “Some of the use cases that the specific AMALLOY is suitable for include low buy-to-fly parts for aerospace/aviation (i.e., antennas, aircraft brackets, nanosatellites) and high strength components such as topology optimized engine brackets.”

With AMALLOY, TII presents an innovative aluminum alloy that significantly expands the possibilities of 3D printing and enables new applications in various sectors. The advances in strength, printability and thermal stability mark a significant step in the development of materials for additive manufacturing.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.