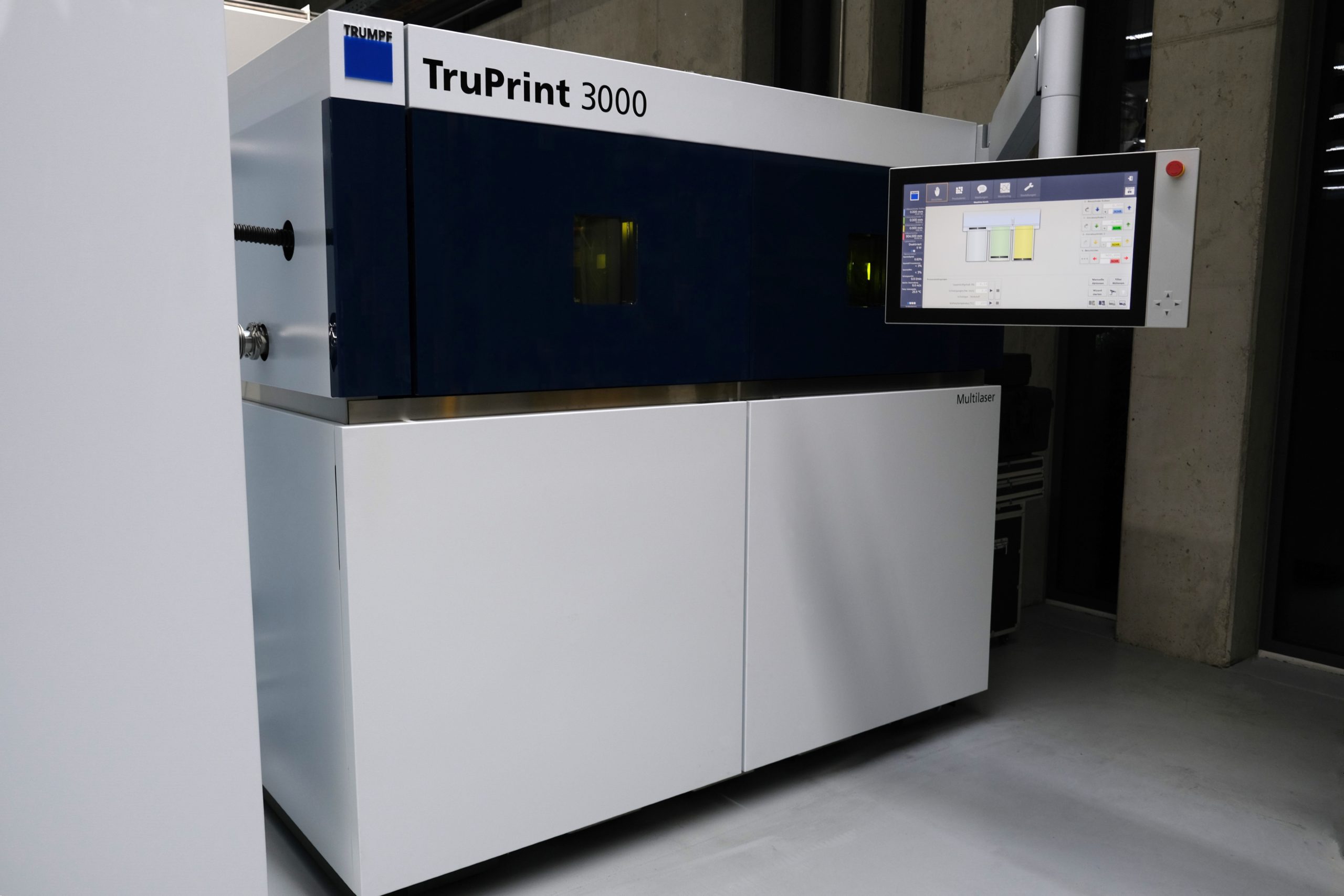

With toolcraft AG‘s latest investment in a TruPrint 3000 from Trumpf, which is equipped with two lasers, the company is setting new standards in terms of quality and efficiency in 3D printing. The decision to invest in this system is based on a long-standing and fruitful collaboration with Trumpf, one of the most renowned suppliers in the field of laser technology.

Additive manufacturing, also known as 3D printing, has become increasingly important in recent years. It enables the fast, flexible and cost-efficient production of components that would be difficult or impossible to manufacture using conventional production methods. Toolcraft, a medium-sized family business, recognized this trend early on and has continuously invested in the expansion of its machinery. With ten L-PBF systems and two machines with powder nozzles, the company is already well positioned to meet the increasing demands of the market.

The TruPrint 3000 is characterized by its dual laser technology and a comprehensive monitoring system. These features guarantee high process stability and reproducibility, which is crucial for applications in critical sectors such as medical technology, aerospace and the semiconductor industry.

“Process stability, reproducibility, service and data security were important decision criteria for us. The cooperation with Trumpf has proven itself over many years, and our long-standing partner was able to fully convince us in all respects,” says Stefan Auernhammer, Head of Additive Manufacturing at Toolcraft. “With the integrated melt pool monitoring system, we want to further deepen our process knowledge and are convinced that we can raise the quality, safety and efficiency of the melting process to the next level.”

By certifying its manufacturing processes in accordance with ISO/ASTM TS 52930:2011 and 52920:2013, Toolcraft is also underlining its commitment to the highest quality standards. The TruPrint 3000 is primarily used for series applications in demanding industrial sectors and promises to further increase the efficiency and cost-effectiveness of additive manufacturing at Toolcraft.

At a time when the demand for customized and technically sophisticated components is constantly growing, Toolcraft is once again positioning itself at the forefront of technological development with this investment. Additive manufacturing is at the cutting edge and companies like Toolcraft are paving the way for a future in which the boundaries of traditional manufacturing processes are becoming increasingly blurred.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.