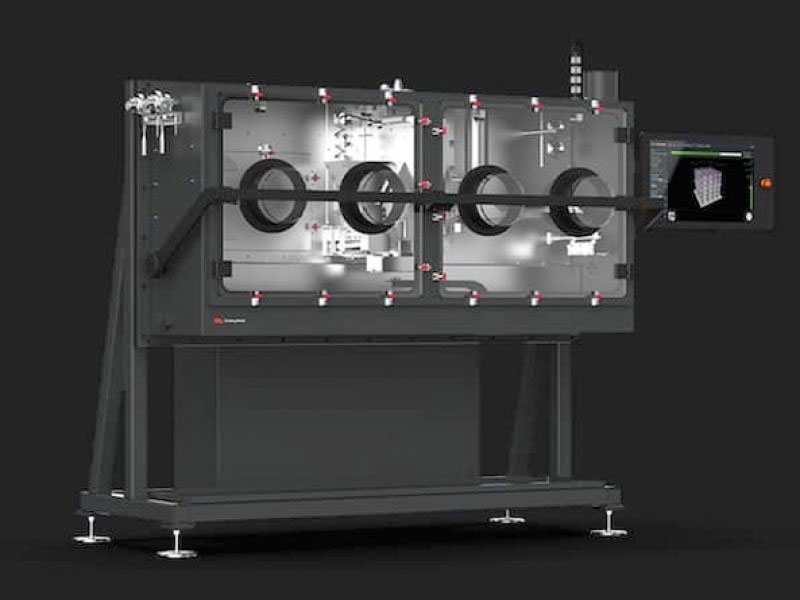

Materials manufacturer Uniformity Labs announces the availability of its UniJet SS17-4PH Performance ultra-low porosity 17-4PH stainless steel powder for the Desktop Metal Production System.

Testing on Desktop Metal’s Production System shows excellent physical and mechanical properties of UniJet 17-4PH. The powder delivers high green strength and lower shrinkage.

One of the main advantages of UniJet 17-4PH is its exceptional bulk and tapped density, which results in green parts with many more interparticle contact points and higher density (10% lower relative porosity) than standard binder jetting powders. This enables green parts with almost twice the transverse fracture strength across all layer thicknesses.

Such green parts, along with the very high flowability of the Uniformity powder, make the production of more complex thin-walled or heavier green parts with larger aspect ratios possible by minimizing fracture during deflashing of large high aspect ratio parts and geometrically complex parts with fine features and channels.

“The application of Uniformity UniJet 17-4 PH stainless steel for BJT delivers mechanical and process excellence for our customers who require materials that perform to the highest standards across each step of the production process,” said Uniformity founder and CEO Adam Hopkins. “Our powders deliver superior mechanical properties, printing yield, and process stability, delivering repeatable production scale binder jetting.”

“Desktop Metal is delighted to offer this highly advanced 17-4 PH stainless steel powder from Uniformity Labs for our Production System platform,” said Ric Fulop. Founder and CEO of Desktop Metal. “This latest addition to our material portfolio allows us to binder jet 17-4 PH stainless steel materials critical to producing complex designs. Binder jetting powders processed with Uniformity Labs technology enables unmatched mechanical properties and can further improve the economics of printing. We look forward to continuing to collaborate with the Uniformity team.”

Shri Shetty, CEO of Zeda and a partner of Uniformity Labs, said, “This is not the first time we’ve partnered together to develop materials, and Uniformity’s powders have a history of exhibiting superior mechanical properties and higher machine productivity, which will help us further our mission to build things better together in the medical device industry.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.