Velo3D, Inc., a leader in additive manufacturing technology for critical metal parts, introduces Developer, an innovative enhancement to its flow print preparation software. This innovation gives users unparalleled visibility and control over print parameters in the 3D printing process.

The flexibility of Flow Developer allows users to transfer their experience and knowledge from previous projects, develop new material processes and control their optimization goals. This greatly simplifies the transition from additive manufacturing projects to Velo3D’s fully integrated solution.

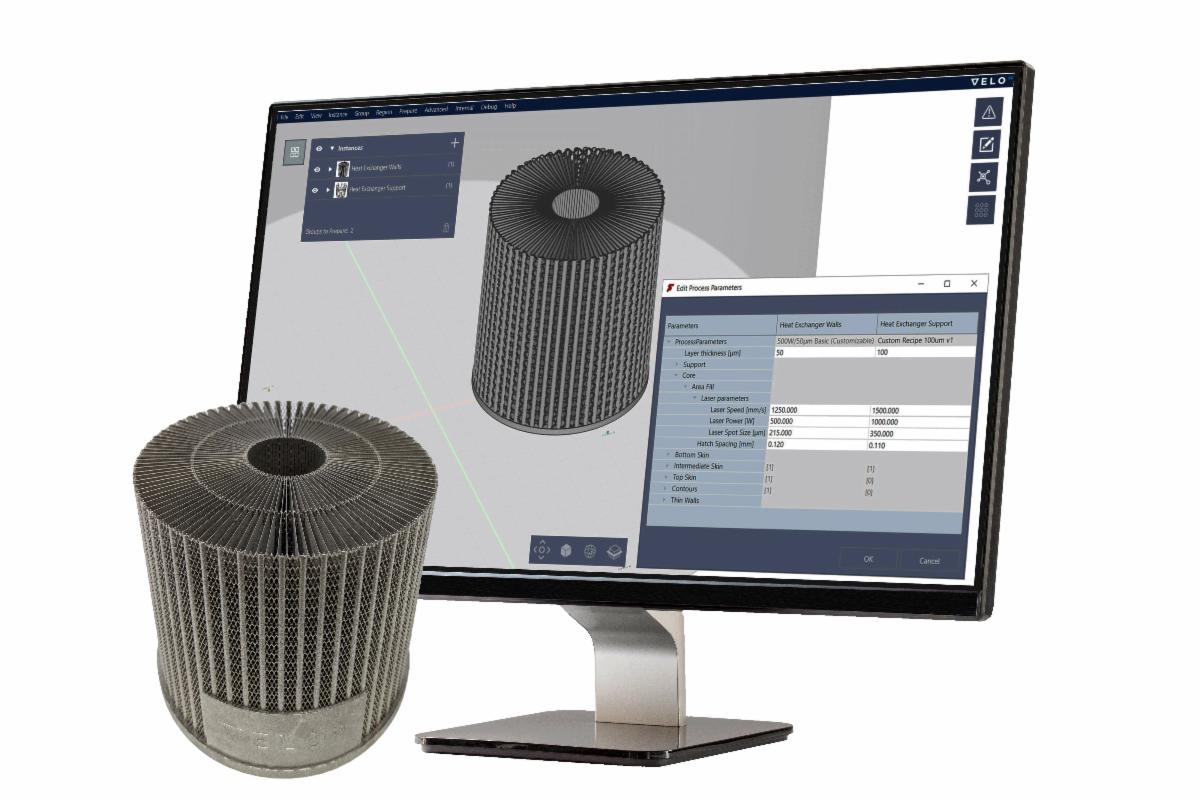

Flow Developer is available for users of Flow 7.0, the latest version of Velo3D’s print preparation software that seamlessly converts traditional design files into print files. With editor access to print parameters, Developer gives organizations maximum flexibility and control when working with their Velo3D additive manufacturing solution. Users can import proven parameters, optimize standard parameters for specific application needs and develop parameter sets for the development of new materials and specific applications. Once a part produced with Developer has been qualified, users can scale production utilizing the control, quality and repeatability of Velo3D’s additive manufacturing solution.

“It can be a challenge to produce repeatable results across different metal 3D printers—even when they’re the same model of printer—however, Velo3D’s solution can consistently produce parts within spec across any of its printers, which provides huge benefits for companies looking to scale production of their parts,” said Additive Manufacturing Manager at Ursa Major, Thomas Pomorski. “When our team first tested Flow Developer, we transferred parameters we developed on a non-Velo system, hoping we could easily produce the same part on Velo3D’s system and then take advantage of the scalability it provides. On our first try, we imported a part with highly complex, sensitive features and achieved incredible results that were within specification. Since then, we’ve accomplished the same process with other parts and in some cases, have been able to reduce print time by nearly 50% without sacrificing accuracy or quality.”

Prior to its general release, Developer was made available for feedback to selected customers, including Ursa Major, a privately funded company developing rocket engine technology. During this phase, engineers were able to transfer their custom parameters directly into their Velo3D solutions and achieved exceptional results.

“Velo3D’s mission has always been to provide an additive manufacturing solution that delivers repeatability from machine-to-machine, which is still a big shortcoming with legacy metal 3D printers,” said Brad Kreger, CEO of Velo3D. “Previously, we did this by providing pre-defined parameters within the system, which left customers wanting to know what’s inside our ‘black box’ and looking for more flexibility. When you combine Flow Developer with our ability to produce identical parts using the same print file, we strike the perfect balance between usability, repeatability, and flexibility. This has allowed these early access customers to think outside the box of conventional additive manufacturing to progress beyond their current limitations and realize true production scalability for their parts.”

Flow is a central component of Velo3D’s unique approach to additive manufacturing, differentiating itself from competitive offerings with a fully integrated solution that includes hardware and software and ensures consistency from machine to machine. In addition to Flow and the Sapphire family of printers, the company’s solution also includes Assure quality assurance software, which monitors a print layer-by-layer to ensure consistent geometric accuracy, surface finish and material properties throughout a finished part.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.