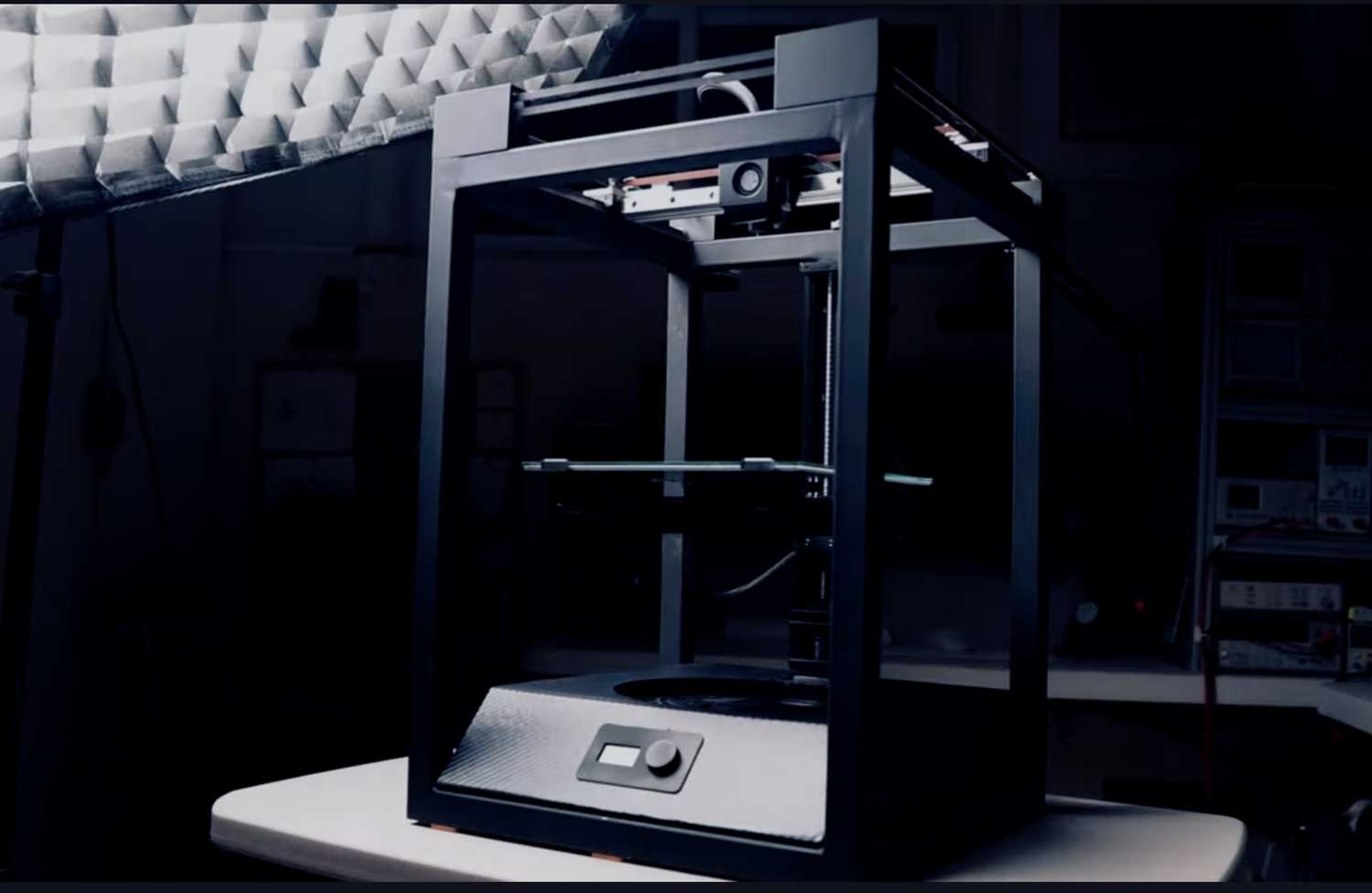

In a DIY project, the YouTube channel TechBuilder constructed a core XY 3D printer from inexpensive components. The aim was to create a low-cost DIY printer with high production quality.

The frame was a self-welded lattice frame made from 1×1 inch steel tubes for around 4 US dollars. Despite the lack of professional equipment, it was possible to create an amazingly precise basic frame by meticulously adjusting the angles. Used THK linear guides were also used for the XY linear guides.

Many small parts such as motors, pulleys and brackets came from an in-house spare parts warehouse. Even the hotend and heating bed use leftover parts from an old 3D printer. Numerous printed parts made from recycled filament complete the DIY construction.

TechBuilder’s Core-XY is powered by a silent board in the form of the BigTreeTech SKR Mini E3 V3. Customs firmware controls the unusual kinematics and compensates for slight manufacturing tolerances through calibration.

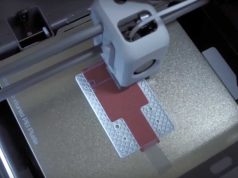

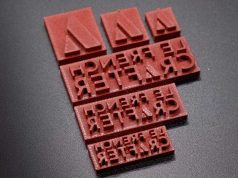

In test prints, the custom build achieved amazing detail quality despite simple Bowden feed. For regular printing tasks, speeds of 150 mm/s at 6000 mm/s² acceleration proved their worth. With a ceramic hotend and optimized settings, TechBuilder even achieved speeds of up to 350 mm/s at 15,000 mm/s².

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.