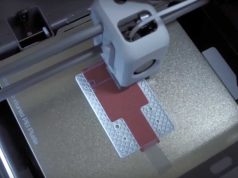

British Youtuber Robert Murray-Smith has compared his own 3D-printed rotor blades with a commercially available fan. In a video, he tests which design moves more air. He makes the 3D model data for the turbine blades available for free on Thingiverse.

According to Murray-Smith, the starting point was a fan with industrially manufactured rotor blades. In order to create a fair comparison, he based his 3D-printed blades on the blade area and number of blades of the original fan.

In his video, the inventor demonstrates a simple practical test: Using a drill, first the original fan, then the 3D-printed blades with his own design are driven and the air speed is measured. The self-printed rotor blades generate visibly more wind than the original. According to Murray-Smith, it also works much more quietly.

As an explanation, the Youtuber cites the shape of his wind turbine blades, which he has optimized. In a previous video, he had replaced the original angular design with a curved shape that improves the air flow. This has now also proven itself in the fan test.

Murray-Smith sees the result as confirmation that his 3D-printed blades are also suitable for other applications such as PC fans or mini wind turbines. He makes the print files available to interested makers free of charge on Thingiverse.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.