Who hasn’t experienced it: standing at a festival or concert and waiting at the bar for what feels like an eternity, only to be served a poorly mixed drink. It was exactly this experience that inspired YouTuber Luis from luisengineering to create an ambitious project: a machine that mixes the perfect Aperol Spritz in seconds.

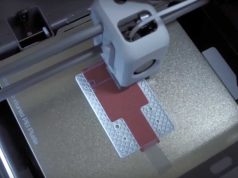

Instead of using expensive robotics, he chose a mechanical approach. He conceived a design in which the ingredient bottles are positioned upside down so that the liquids can flow out easily. Valve blocks with specially calibrated orifices are used to set the correct mixing ratio.

A lever actuates the valves and at the same time feeds the ready-mixed drink into the glass via a chute. The machine needs just 5 seconds for an Aperol Spritz. However, in a test run in the garden with real Aperol and sparkling wine, it became apparent that the sparkling wine foamed too much and the chute overflowed. Adjustments to the design solved this problem.

As the inventor explains on his YouTube channel, the development process was quite challenging. Initially, the valves were not completely tight, which led to flooding. However, with the help of 3D-printed parts, seals and fine adjustments, it was possible to get the teething troubles under control.

After further improvements, the YouTuber finally presented his creation to friends, who were very impressed. However, he also admits that the machine could be further optimized. For this reason, he is posting all the 3D printing data and a parts list online so that others can continue his work.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.