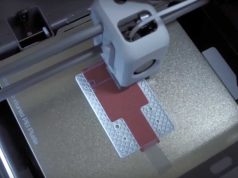

It is almost impossible to produce a perfectly shaped wooden ball without the help of a machine. Industrial ball machines are extremely expensive and far too bulky for home use. For this reason, YouTuber and maker Fraens designed, built and tested a 3D-printed ball machine.

The machine is comparatively simple in design and should be able to be assembled by anyone who can hold a screwdriver. According to Fraens, the 3D printing process is easy to carry out as the components are designed in such a way that they can be printed without support structures. He recommends PLA/PETG or ABS as printer materials. Due to the forces and vibrations that occur during the grinding process, Fraens recommends a fill rate of 30%.

In his video, Fraens also explains in detail how the ball machine is assembled and how it works. The sanding process takes a few hours but, according to Fraens, rewards you with perfectly shaped wooden balls.

Fraens provides the complete assembly instructions with all .stl files, links to the required parts and an assembly drawing on the Cults3D platform for 25 euros.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.