In 3D printing, objects can be made significantly lighter and more material-efficient through the use of infill structures on the inside. But how do the different patterns affect strength? The YouTube channel Slant 3D has subjected different variants to a print test.

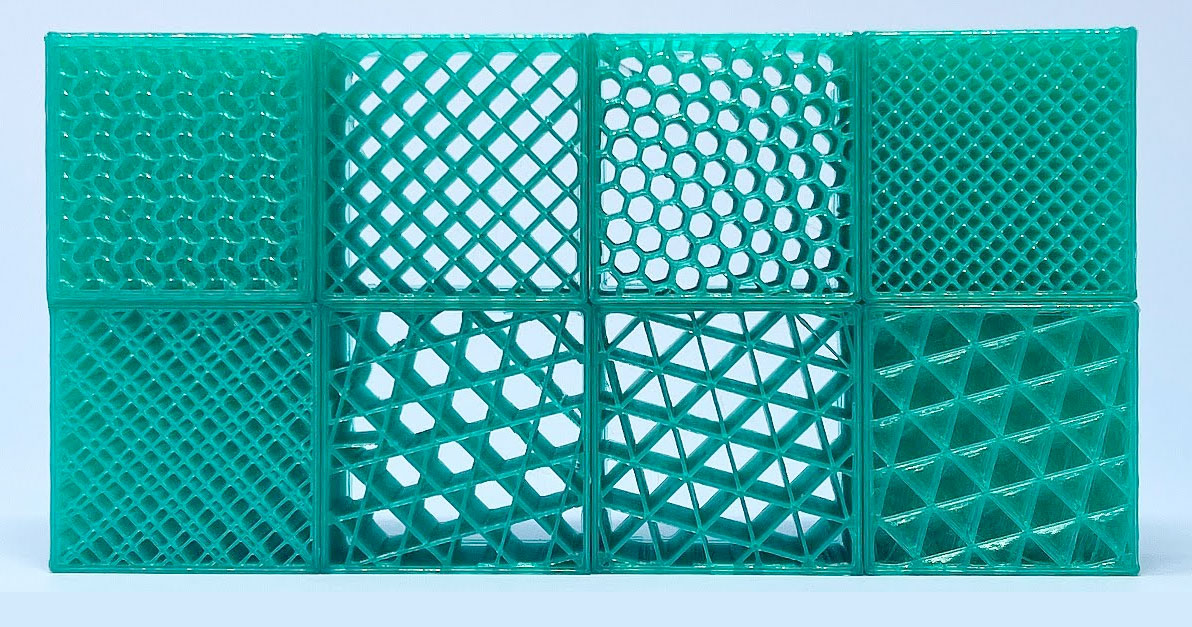

In the experiment, cubes with seven common infill patterns such as grids, triangles and honeycombs were printed at a density of 20%. The compressive strength was then determined.

It was found that the cubic structure was the most resistant and had no fractures. Lattice and triangular infills, on the other hand, broke early. Linear infill proved to be very resilient in compression.

According to the Slant 3D, however, it’s not just maximum strength that matters. Factors such as air permeability and printing time must also be taken into account. For example, although honeycombs are suitable in principle, they increase the printing time.

Overall, the test makes it clear that mechanical properties can be specifically set via the infill pattern. Which structure is ideal depends on the application. The optimum can be found by varying parameters such as density.

Finally, the video shows all tested infill variants in action.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.